I’m going to warn you, this post sucks!

In 2017 I made my own cyclone dust separator with a Ridgid 16 gallon vac. It worked pretty well, but left me wanting something better. Some of the things I wanted in a new system are:

- More power

- Larger container

- Stationary unit

- Better filtration

What I needed/wanted was something around two horsepower and the clear winner in that category is the one from Harbor Freight. Nothing else even comes close to their price, especially after using a 20% or 25% coupon. In order to make it work really well it needs a lot of mods though.

I looked at some of the complete solutions available and they cost at least a grand. I spent about $540 and could have saved around $100 by going with a cheaper hose and getting creative with connectors. Here’s what I bought:

Sucked my wallet dry!

This is a common project in the woodworking community, so Google can show you to a lot of variations. This 2010 post on lumberjocks.com is almost exactly what I was going for, including the trash can Thien cyclone separator baffle.

Before I get into it, here is the what the Harbor Freight dust collector looks like when it’s assembled and not modified.

I took a few photos during my build. First task was some knolling.

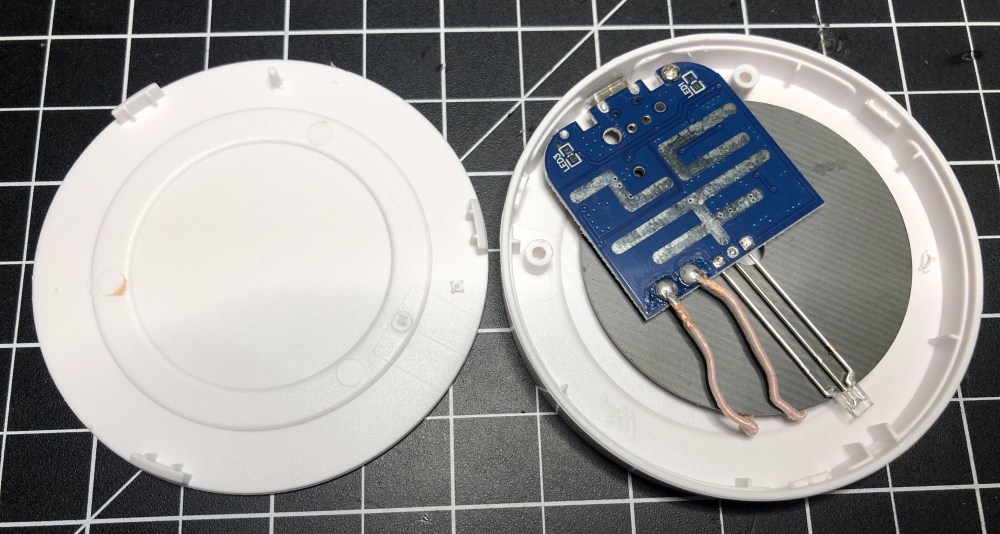

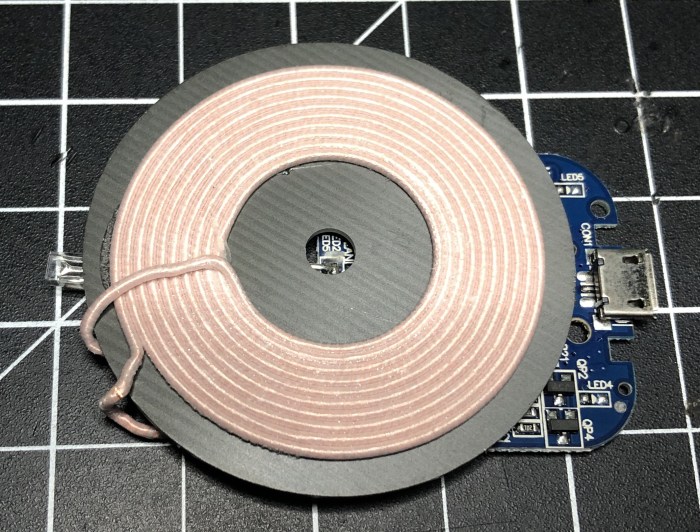

I installed the cyclone kit on the trash can cover and made a Thien baffle.

A very ugly cart was made using scrap wood. The only 2x4s I had were extremely twisted.

I wasn’t sure how the stand was going to support the weight of the motor. Does fine though. I can make it lean if I push on it, but it’s not going to fall over. Most of the time it’ll be sitting in a corner also supported by the trash can under it.

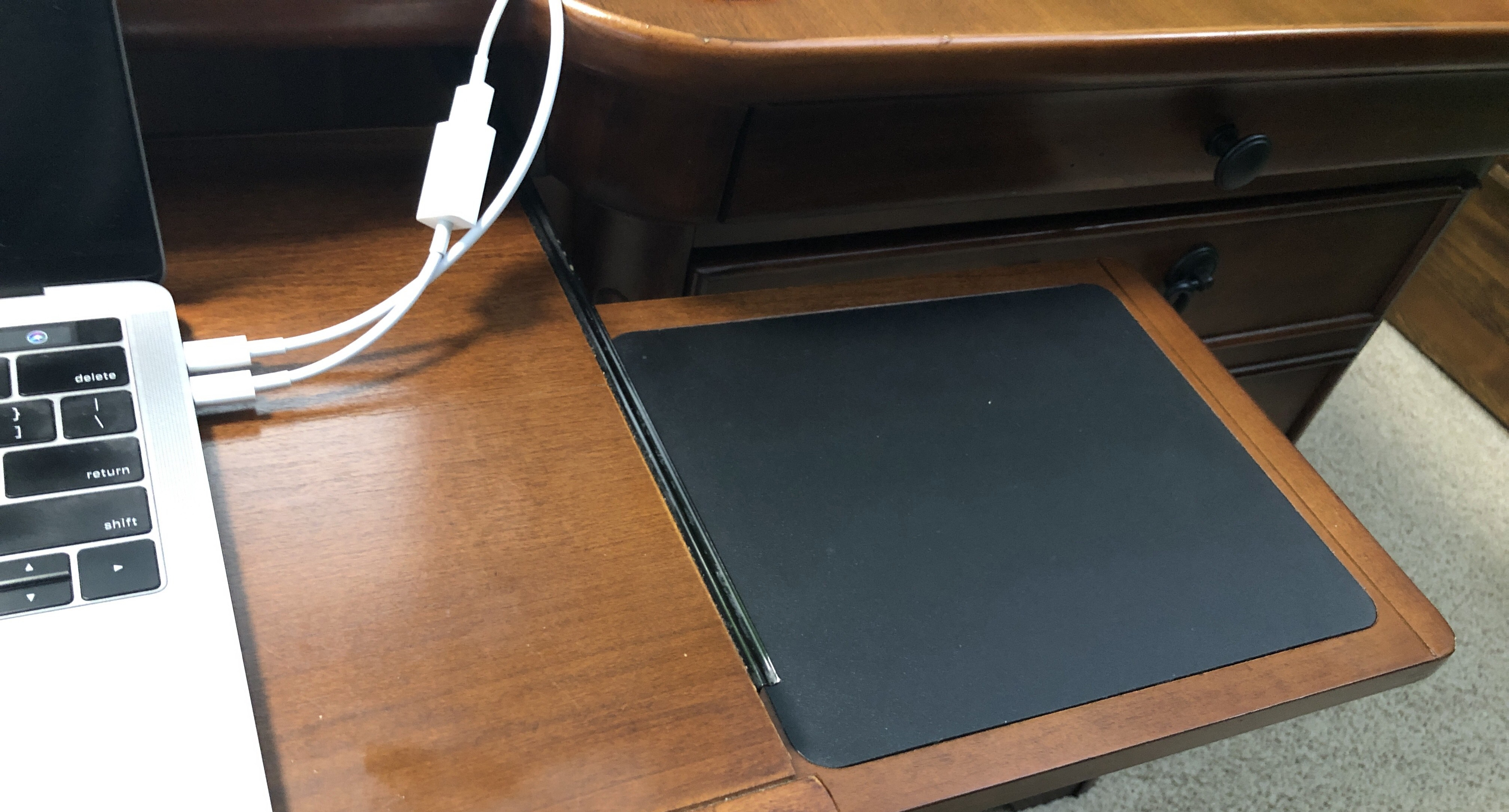

These risers combine with a makeshift wedge, propping up the trash can to mate with the motor.

Here’s the “wedge” platform. I made a design change after the stand had already been built, otherwise it could have been much shorter.

With the trash can and motor jacked up, these layered blocks raise up the bag holder and filter.

Two coats of black spray paint.

Turned out great, but it takes up a lot of space!

The above picture was featured in Stumpy Nubs video The WORST things you can do in a dusty woodshop.

How is the performance though? I hooked the hose up to my table saw and it started pulling old sawdust out of the saw body. I could actually see things swirling around in there. Huge improvement!

As usual, this project ended up being more work than I expected. I’m really happy with the end result and how well it works. Another upgrade I could make in the future would be to install a larger Rikon impeller for even more airflow.

I’ll have to create some adapters for tools with dust ports smaller than 4″, though the hose kit did come with some for use with 2.5″ ports. Now that I have a system with enough power I can build something around the miter saw.