If you have Badger water meters with the Orion Endpoint GIF2014W-OSE, this post should help you read the data for use in Home Assistant. Here is what my meters look like. I have separate lines and meters for the house and outdoor, since they get charged at different rates.

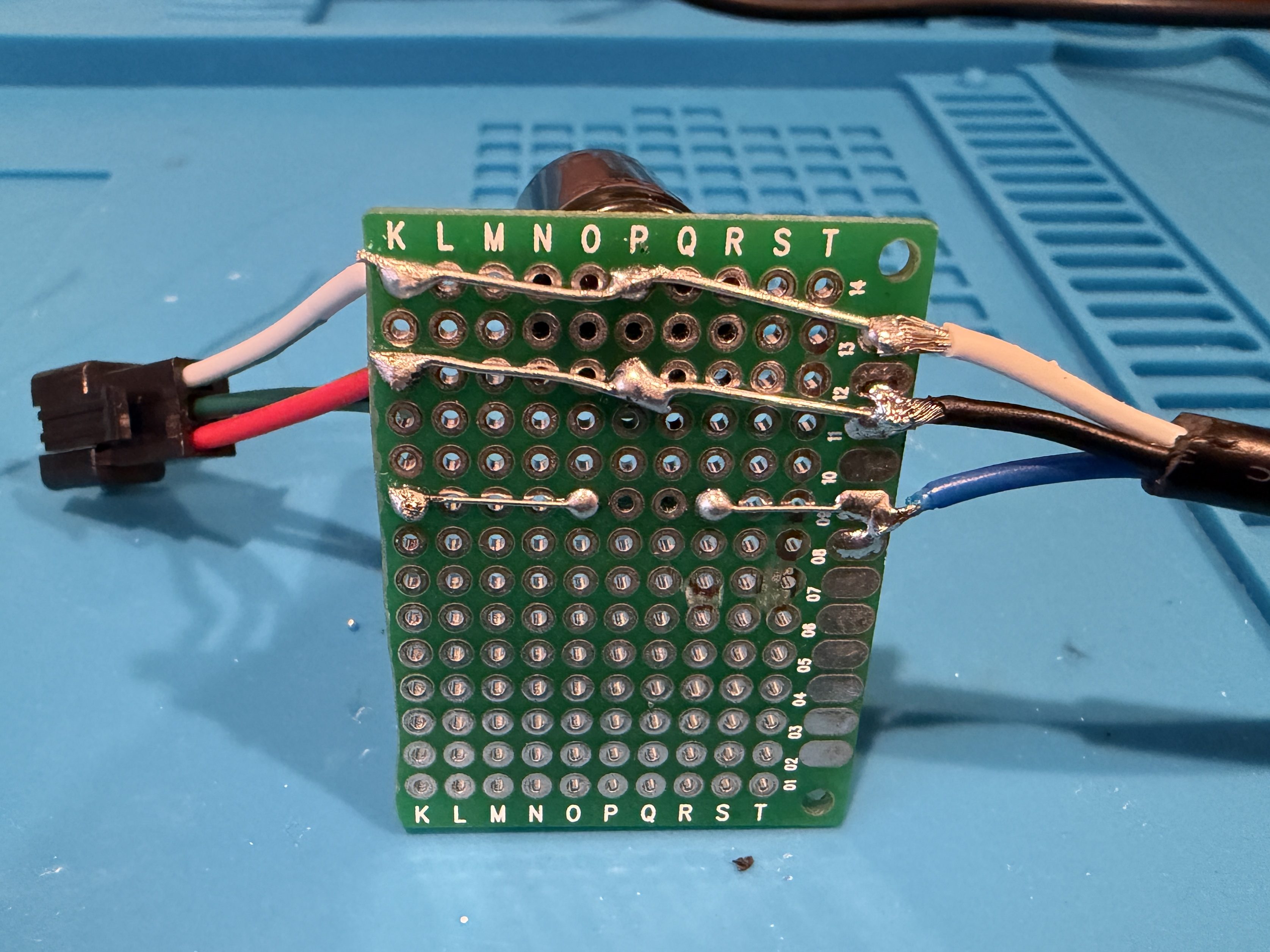

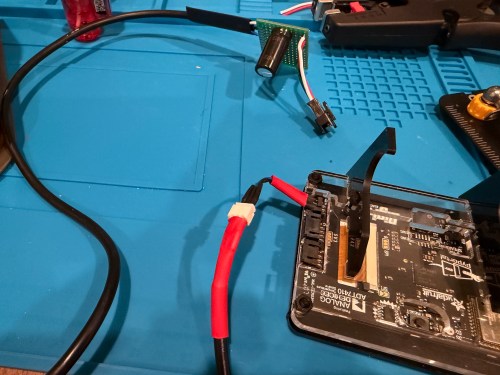

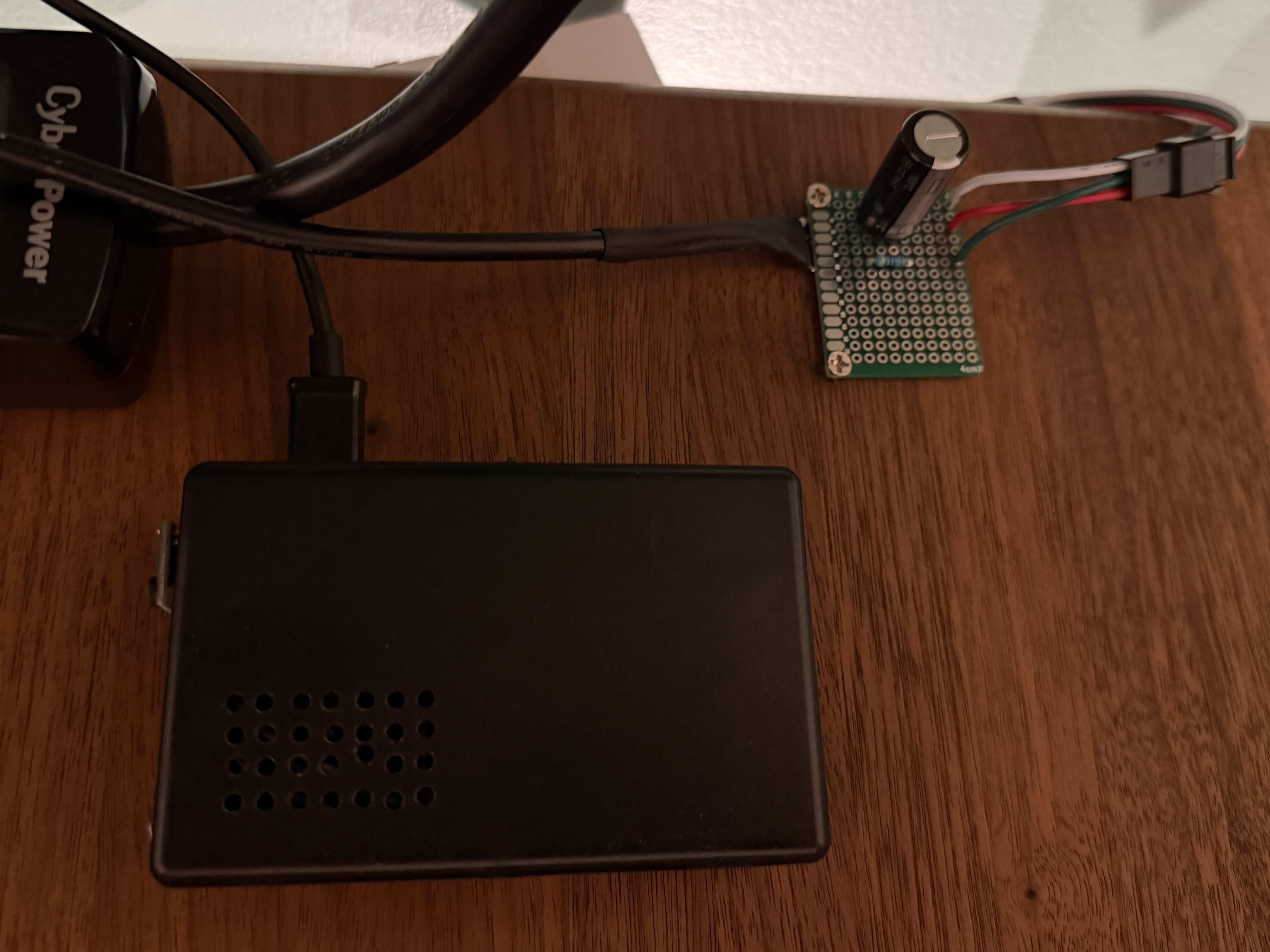

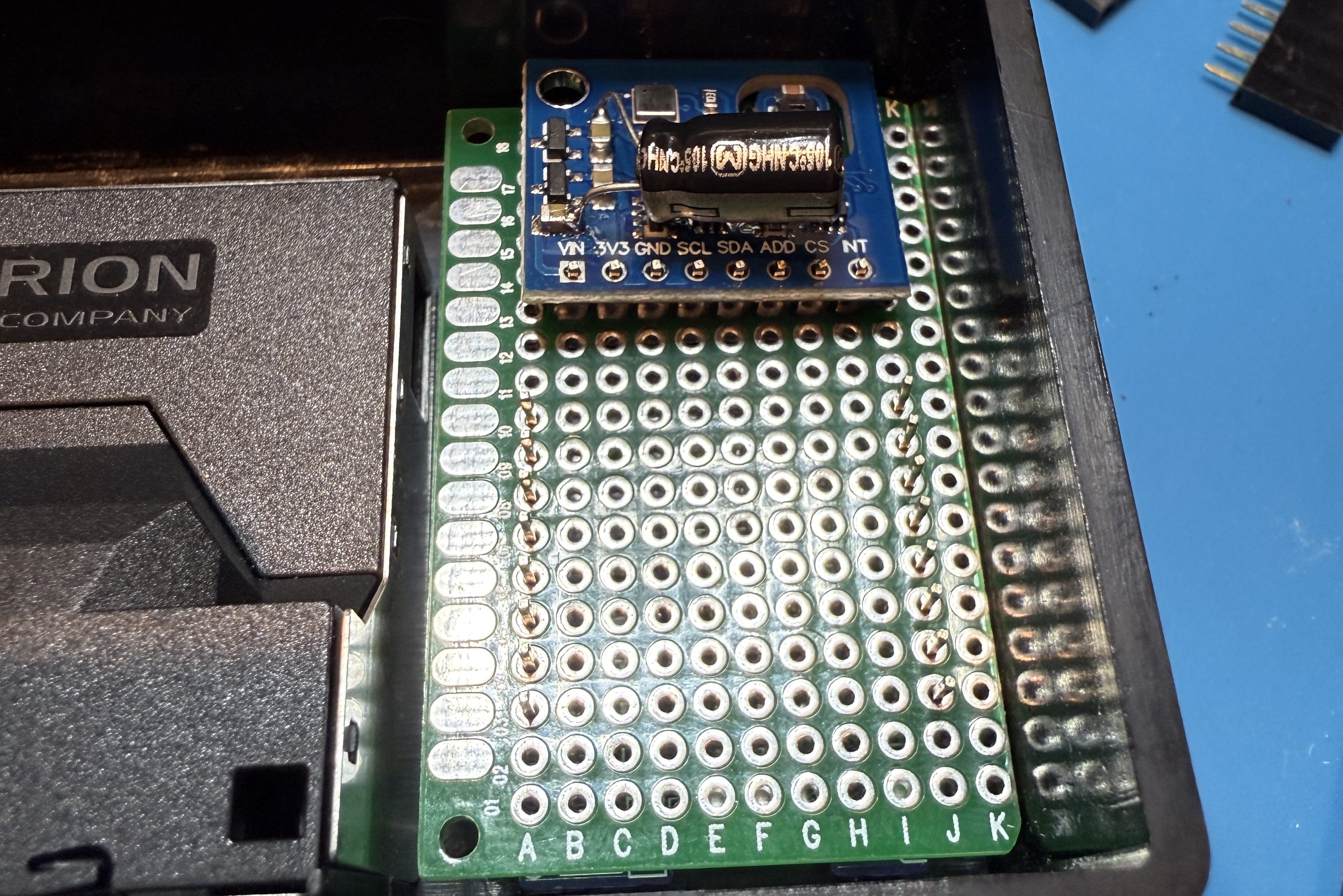

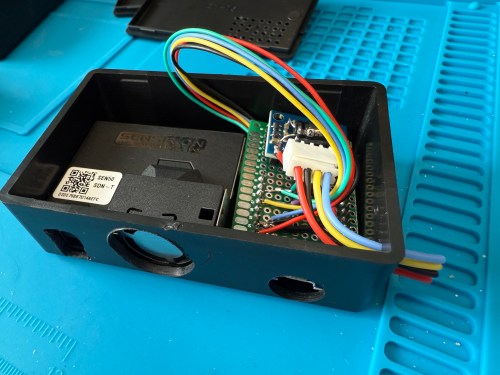

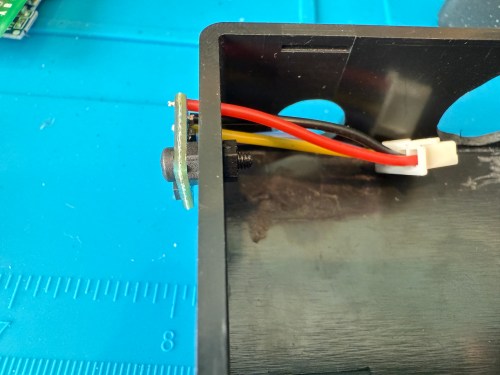

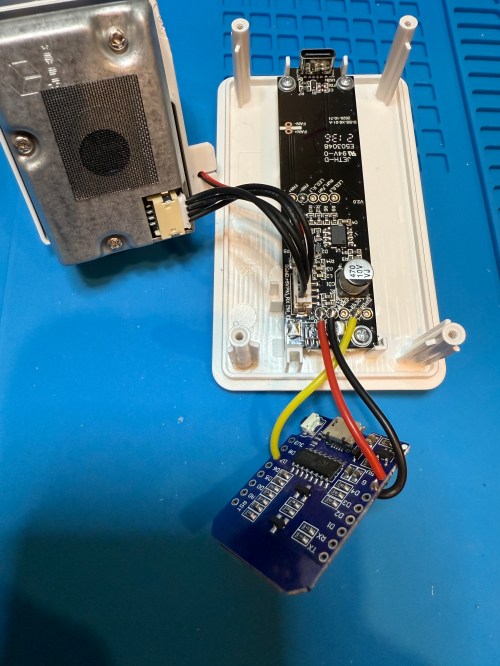

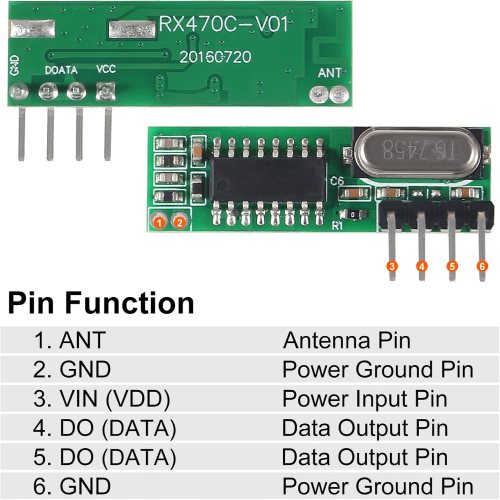

The GIF2014W-OSE broadcasts data from the water meter over radio frequency (RF). Monthly or quarterly the township water department drives around neighborhoods reading these RF signals to determine everyone’s water usage. You can read the same data with a software defined radio (SDR). I’m using a RTL-SDR Blog V4 dongle with a 915MHz LoRa Antenna and ferrite beads (to filter noise) on a USB extension cable. It plugs directly in to my Home Assistant server.

If you want to test the SDR on your computer before setting everything up in Home Assistant check out the rtl_433 repo on GitHub.

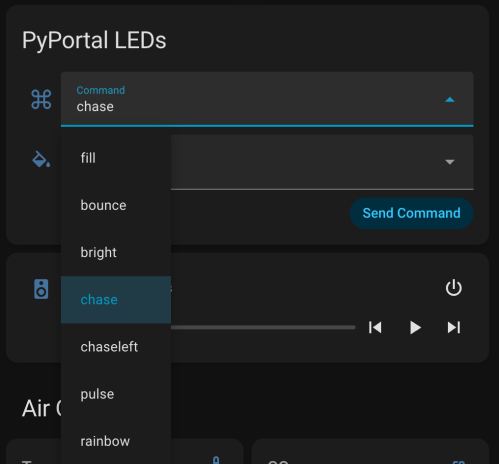

To get started in HA, make sure you’re running a MQTT broker. I use the recommended Mosquitto broker. Install the MQTT Explorer and rtl_433 (next) apps. Note, the main rtl_433 HA app wasn’t updated yet with the latest version of rtl_433, which is needed for the GIF2014W-OSE, so that’s why I had to use the (next) version. It may be updated by the time you’re reading this.

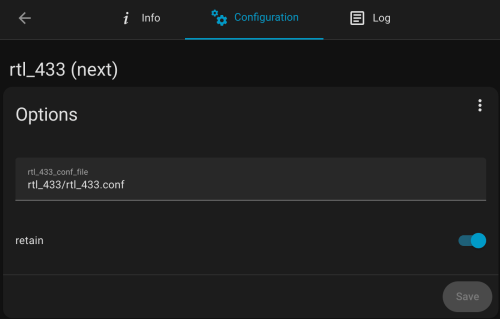

The configuration for the rtl_433 (next) app is stored in a file. I have mine at /homeassistant/rtl_433/rtl_433.conf and here is how my app configuration looks.

Below is a good start for the config file’s contents. Put in your IP address, user, and password.

sample_rate 1600k

gain 28

hop_interval 22

pulse_detect autolevel

pulse_detect minlevel=-35

report_meta level

report_meta noise

report_meta stats:1

output mqtt://[MQTT_IP],user=[MQTT_USER],pass=[MQTT_PASSWORD],retain=1

protocol 282

frequency 905.3M

frequency 906.1M

frequency 906.9M

frequency 907.7M

frequency 908.5M

frequency 909.3M

frequency 910.1M

frequency 910.9M

frequency 911.7M

frequency 912.5M

frequency 913.3M

frequency 914.1M

frequency 914.9M

frequency 915.7M

frequency 916.5M

frequency 917.3M

frequency 918.1M

frequency 918.9M

frequency 919.7M

frequency 920.5M

frequency 921.3M

frequency 922.1M

frequency 922.9M

frequency 923.7M

The water meter endpoint broadcasts across the range of 904.4 to 924.6Mhz and this is going to hop between the 24 frequencies (taken from a GitHub comment) listed in the config every 22 seconds. You may need to tweak the gain, pulse_detect, and other settings depending on your setup. Use your favorite AI to help. If you these next couple of lines to the config file you can see more of what happening, but I wouldn’t leave these in after everything is working.

verbose 7

output json

output log

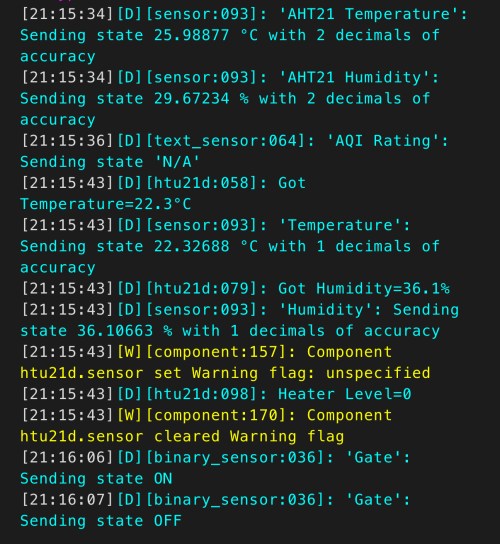

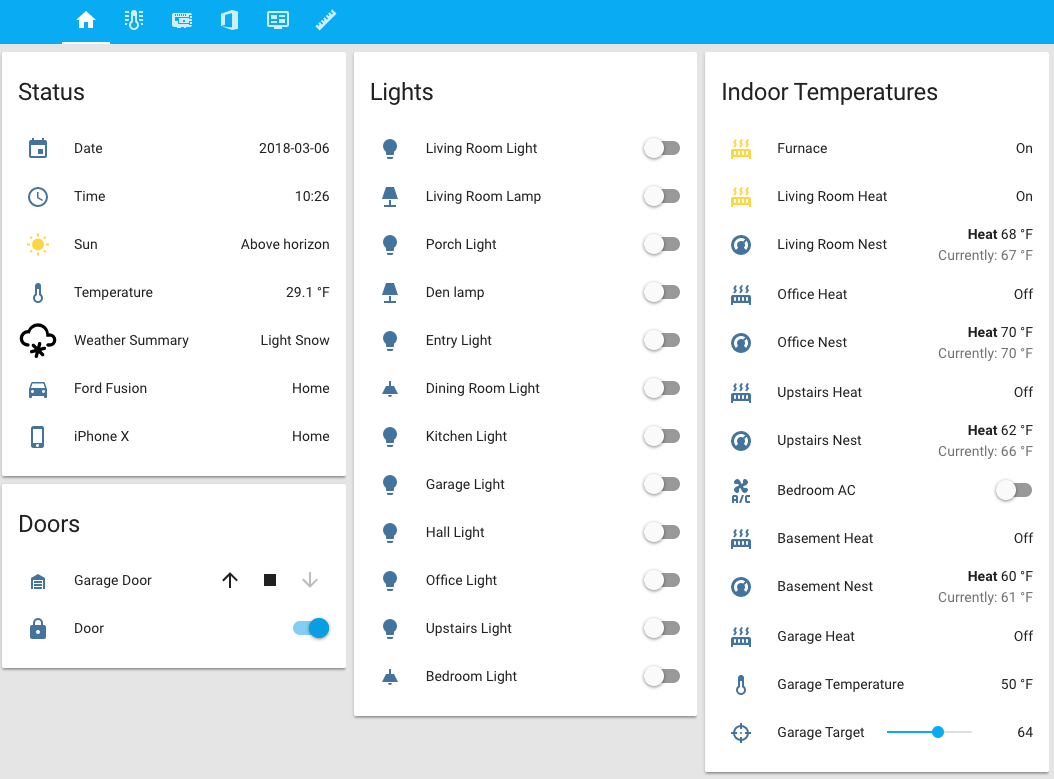

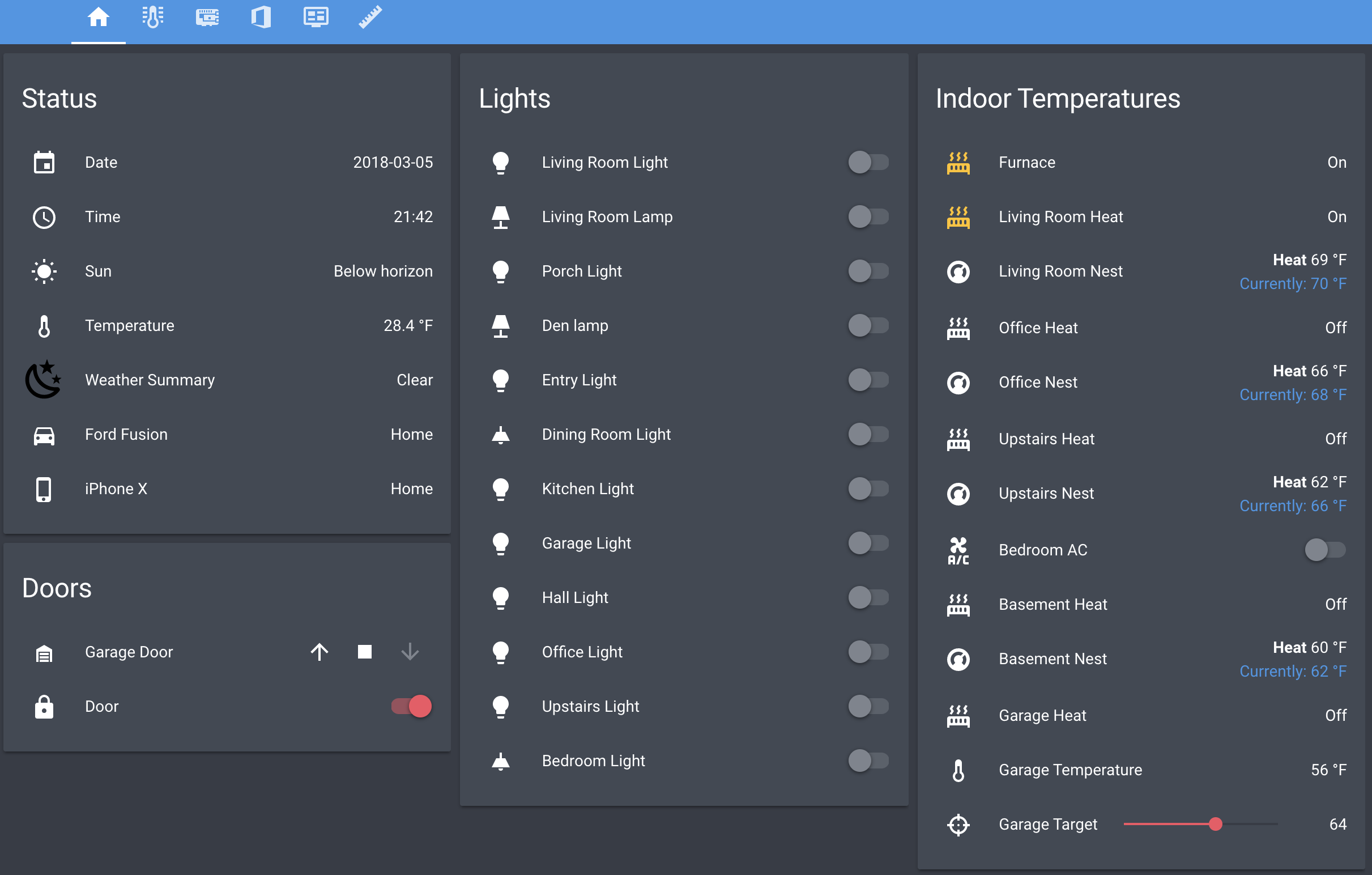

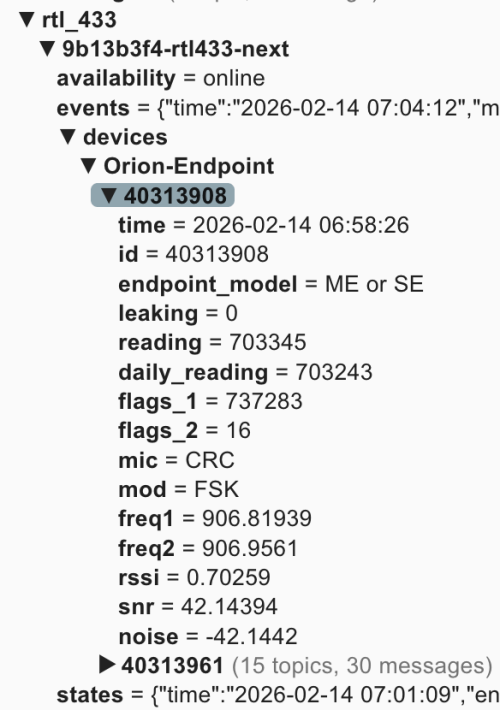

You can view the HA app’s logs to see more details. When everything is running, open up MQTT Explorer and look for the rtl_433 topics. Hopefully within an hour or two you’ll see something similar to this.

In this screenshot 40338908 and 40313961 are the ids for my meter endpoints. You may see a bunch of other ids for other meters in your neighborhood. You may have physical tags on the devices with their IDs or you can compare the reading values to what is displayed on the water meter.

Now this data can be brought in to Home Assistant. It’ll take some tinkering and customization to fit it all for your HA install. I’m also writing this over a week after setting everything up, so I don’t remember the order of adding everything, but you should be able to do most of it at once and restart. Make sure to update the name, unique_id, source, and state everywhere to fit your needs. The state_topic‘s need to match what you see in MQTT Explorer, and any other cross references have to match your renames. Only use what applies to your situation. If you only have one meter, remove all the outdoor/sprinkler stuff. I’m scraping the Saginaw Township water rates from their web site, so that stuff is going to be very custom, but gives you an idea of what you can do.

In configuration.yaml:

mqtt:

binary_sensor:

- name: "House Water Meter Leak"

unique_id: "house_water_meter_leak"

state_topic: "rtl_433/9b13b3f4-rtl433-next/devices/Orion-Endpoint/40313908/leaking"

payload_on: "1"

payload_off: "0"

device_class: moisture

- name: "Outdoor Water Meter Leak"

unique_id: "outdoor_water_meter_leak"

state_topic: "rtl_433/9b13b3f4-rtl433-next/devices/Orion-Endpoint/40313961/leaking"

payload_on: "1"

payload_off: "0"

device_class: moisture

sensor:

- name: "House - Water Meter"

unique_id: "house_water_meter"

state_topic: "rtl_433/9b13b3f4-rtl433-next/devices/Orion-Endpoint/40313908/reading"

unit_of_measurement: "gal"

device_class: water

state_class: total_increasing

icon: mdi:water-pump

value_template: "{{ value | float(0) / 10 }}"

- name: "House - Water Meter Daily Snap"

unique_id: "house_water_meter_daily_snap"

state_topic: "rtl_433/9b13b3f4-rtl433-next/devices/Orion-Endpoint/40313908/daily_reading"

device_class: water

state_class: total

unit_of_measurement: "gal"

entity_category: diagnostic

icon: mdi:history

value_template: "{{ value | float(0) / 10 }}"

- name: "House - Water Meter - Freq 1"

unique_id: "house_water_meter_freq1"

state_topic: "rtl_433/9b13b3f4-rtl433-next/devices/Orion-Endpoint/40313908/freq1"

value_template: "{{ value | float(0) }}"

unit_of_measurement: "MHz"

state_class: measurement

device_class: frequency

- name: "House - Water Meter - Freq 2"

unique_id: "house_water_meter_freq2"

state_topic: "rtl_433/9b13b3f4-rtl433-next/devices/Orion-Endpoint/40313908/freq2"

value_template: "{{ value | float(0) }}"

unit_of_measurement: "MHz"

state_class: measurement

device_class: frequency

- name: "Outdoor - Water Meter"

unique_id: "water_meter_outdoor"

state_topic: "rtl_433/9b13b3f4-rtl433-next/devices/Orion-Endpoint/40313961/reading"

unit_of_measurement: "gal"

device_class: water

state_class: total_increasing

icon: mdi:water-pump

value_template: "{{ value | float(0) / 10 }}"

- name: "Outdoor - Water Meter Daily Snap"

unique_id: "outdoor_water_meter_daily_snap"

state_topic: "rtl_433/9b13b3f4-rtl433-next/devices/Orion-Endpoint/40313961/daily_reading"

device_class: water

state_class: total

unit_of_measurement: "gal"

entity_category: diagnostic

icon: mdi:history

value_template: "{{ value | float(0) / 10 }}"

- name: "Outdoor - Water Meter - Freq 1"

unique_id: "outdoor_water_meter_freq1"

state_topic: "rtl_433/9b13b3f4-rtl433-next/devices/Orion-Endpoint/40313961/freq1"

value_template: "{{ value | float(0) }}"

unit_of_measurement: "MHz"

state_class: measurement

device_class: frequency

- name: "Outdoor - Water Meter - Freq 2"

unique_id: "outdoor_water_meter_freq2"

state_topic: "rtl_433/9b13b3f4-rtl433-next/devices/Orion-Endpoint/40313961/freq2"

value_template: "{{ value | float(0) }}"

unit_of_measurement: "MHz"

state_class: measurement

device_class: frequency

scrape:

- resource: https://saginawtownship.org/departments/public_services/water_distribution.php

scan_interval: 86400

sensor:

- name: "Saginaw House Water Rate Raw"

select: "article ul li"

index: 2

value_template: >

{{ value | regex_findall_index('Combined:\s*\$?\s*(\d+\.\d+)', ignorecase=True) }}

- name: "Saginaw Outdoor Water Rate Raw"

select: "article ul li"

index: 2

value_template: >

{{ value | regex_findall_index('\(Sprinkler Meter\)\s*\$?\s*(\d+\.\d+)', ignorecase=True) }}

utility_meter:

house_daily_water:

name: "House Daily Water"

unique_id: house_daily_water

source: sensor.house_water_meter

cycle: daily

always_available: true

outdoor_daily_water:

name: "Outdoor Daily Water"

unique_id: outdoor_daily_water

source: sensor.water_meter_outdoor

cycle: daily

always_available: true

In templates.yaml:

- binary_sensor:

- name: "Outdoor Water Flowing Hourly"

unique_id: outdoor_water_flowing_hourly

device_class: moving

state: >

{{ states('sensor.outdoor_water_hourly_change') | float(0) > 0 }}

- name: "House Water Flowing Hourly"

unique_id: house_water_flowing_hourly

device_class: moving

state: >

{{ states('sensor.house_water_hourly_change') | float(0) > 0 }}

- name: "Sprinklers Watering"

unique_id: sprinklers_watering

device_class: running

state: >

{{ is_state('binary_sensor.sprinkler_zone_1_watering', 'on')

or is_state('binary_sensor.sprinkler_zone_2_watering', 'on')

or is_state('binary_sensor.sprinkler_zone_3_watering', 'on')

or is_state('binary_sensor.sprinkler_zone_4_watering', 'on')

or is_state('binary_sensor.sprinkler_zone_5_watering', 'on')

or is_state('binary_sensor.sprinkler_zone_6_watering', 'on') }}

- name: "Outdoor Water Leak Persistent"

unique_id: outdoor_water_leak_persistent

device_class: problem

delay_on: "02:00:00"

state: >

{% set water_usage = states('sensor.outdoor_water_hourly_change') | float(0) > 0 %}

{% set sprinklers_active = states('sensor.sprinklers_active_last_hour') | float(0) > 0 %}

{{ water_usage and not sprinklers_active }}

- name: "House Water Nightly Leak Possible"

unique_id: house_water_nightly_leak_possible

device_class: problem

state: >

{% if now().hour == 6 and now().minute == 0 %}

{# If water usage increased 7/9 hours from 9p-6a #}

{# (allowing for minor signal lag and missed reads) #}

{{ states('sensor.house_water_flowing_9_hours') | float(0) > 6.8 }}

{% else %}

{{ states('binary_sensor.house_water_nightly_leak_possible') }}

{% endif %}

In automations.yaml:

- id: '1770044944973'

alias: Notify - Water Meter Leak Detected

description: ''

triggers:

- trigger: state

entity_id:

- binary_sensor.house_water_meter_leak

- binary_sensor.outdoor_water_meter_leak

from:

- 'off'

to:

- 'on'

actions:

- action: notify.mobile_app_nickphone

metadata: {}

data:

title: "\U0001F6B0 Water Leak Flag Detected!"

message: The internal leak flag for {{ trigger.to_state.name }} has been triggered. This

usually indicates continuous flow for the last 24 hours.

data:

priority: high

ttl: 0

- id: '1770082584926'

alias: Notify - Outdoor Water Leak

description: Alerts family when unexplained water flow persists for 2 hours

triggers:

- entity_id: binary_sensor.outdoor_water_leak_persistent

from: 'off'

to: 'on'

trigger: state

conditions: []

actions:

- action: notify.mobile_app_nickphone

metadata: {}

data:

data:

priority: high

ttl: 0

tag: outdoor-leak-alert

color: '#ff0000'

title: "\U0001F6B0 Outdoor Water Leak Detected"

message: 'Unexplained water flow has been detected for over 2 hours. Current

hourly rate: {{ states(''sensor.outdoor_water_hourly_change'') }} gal.'

- id: '1770084282355'

alias: Notify - House Water Leak Possible

description: Water meter usage increased every hour from 9p-6a

triggers:

- at: 07:01:00

trigger: time

conditions:

- condition: state

entity_id: binary_sensor.house_water_nightly_leak_possible

state: 'on'

actions:

- data:

title: "\U0001F3E0 House Water Alert"

message: Potential water leak detected! Water usage increased every hour from

9 PM to 6 AM.

data:

priority: high

ttl: 0

tag: house-leak-alert

color: '#ffa500'

action: notify.mobile_app_nickphone

- id: '1770485349188'

alias: Count House Water Meter Frequency Updates

triggers:

- entity_id: sensor.house_water_meter_freq_1

trigger: state

actions:

- target:

entity_id: input_number.house_water_meter_freq1_updates_per_hour

data:

value: '{{ states(''input_number.house_water_meter_freq1_updates_per_hour'')

| float(0) + 1 }}'

action: input_number.set_value

- id: '1770485394121'

alias: Count Outdoor Water Meter Frequency Updates

triggers:

- entity_id: sensor.outdoor_water_meter_freq_1

trigger: state

actions:

- target:

entity_id: input_number.outdoor_water_meter_freq1_updates_per_hour

data:

value: '{{ states(''input_number.outdoor_water_meter_freq1_updates_per_hour'')

| float(0) + 1 }}'

action: input_number.set_value

- id: '1770485452657'

alias: Reset Water Meter Freq Hourly

description: ''

triggers:

- hours: /1

trigger: time_pattern

actions:

- action: input_number.set_value

metadata: {}

target:

entity_id:

- input_number.house_water_meter_freq1_updates_per_hour

- input_number.outdoor_water_meter_freq1_updates_per_hour

data:

value: 0

- id: '1770038217308'

alias: Notify - Saginaw Water Rate Changed

description: ''

triggers:

- entity_id:

- sensor.saginaw_house_water_rate

- sensor.saginaw_outdoor_water_rate

id: rate_changed

trigger: state

alias: Saginaw Water Rate Changes

- entity_id:

- sensor.saginaw_house_water_rate_raw

- sensor.saginaw_outdoor_water_rate_raw

to: unavailable

for:

seconds: 30

id: scrape_failed

trigger: state

alias: Saginaw Water Rate Raw Scrape Changes

actions:

- choose:

- conditions:

- condition: trigger

id: rate_changed

- condition: template

value_template: "{{ trigger.from_state.state not in ['unknown', 'unavailable']

and \n trigger.to_state.state not in ['unknown', 'unavailable'] }}\n"

sequence:

- data:

title: "\U0001F4B0 Water Rate Change"

message: 'Rate for {{ trigger.to_state.name }} has changed! Old Value: ${{

trigger.from_state.state }} New Value: ${{ trigger.to_state.state }}'

data:

priority: high

ttl: 0

action: notify.mobile_app_nickphone

- conditions:

- condition: trigger

id: scrape_failed

sequence:

- data:

title: '⚠️ Scrape Error: Saginaw Water'

message: 'The scrape for {{ trigger.to_state.name }} failed or returned

non-numeric data. Stable value of ${{ states(trigger.entity_id.replace(''_raw'',

'''')) }} is being maintained. Check: https://saginawtownship.org/departments/public_services/water_distribution.php'

data:

priority: high

ttl: 0

action: notify.mobile_app_nickphone

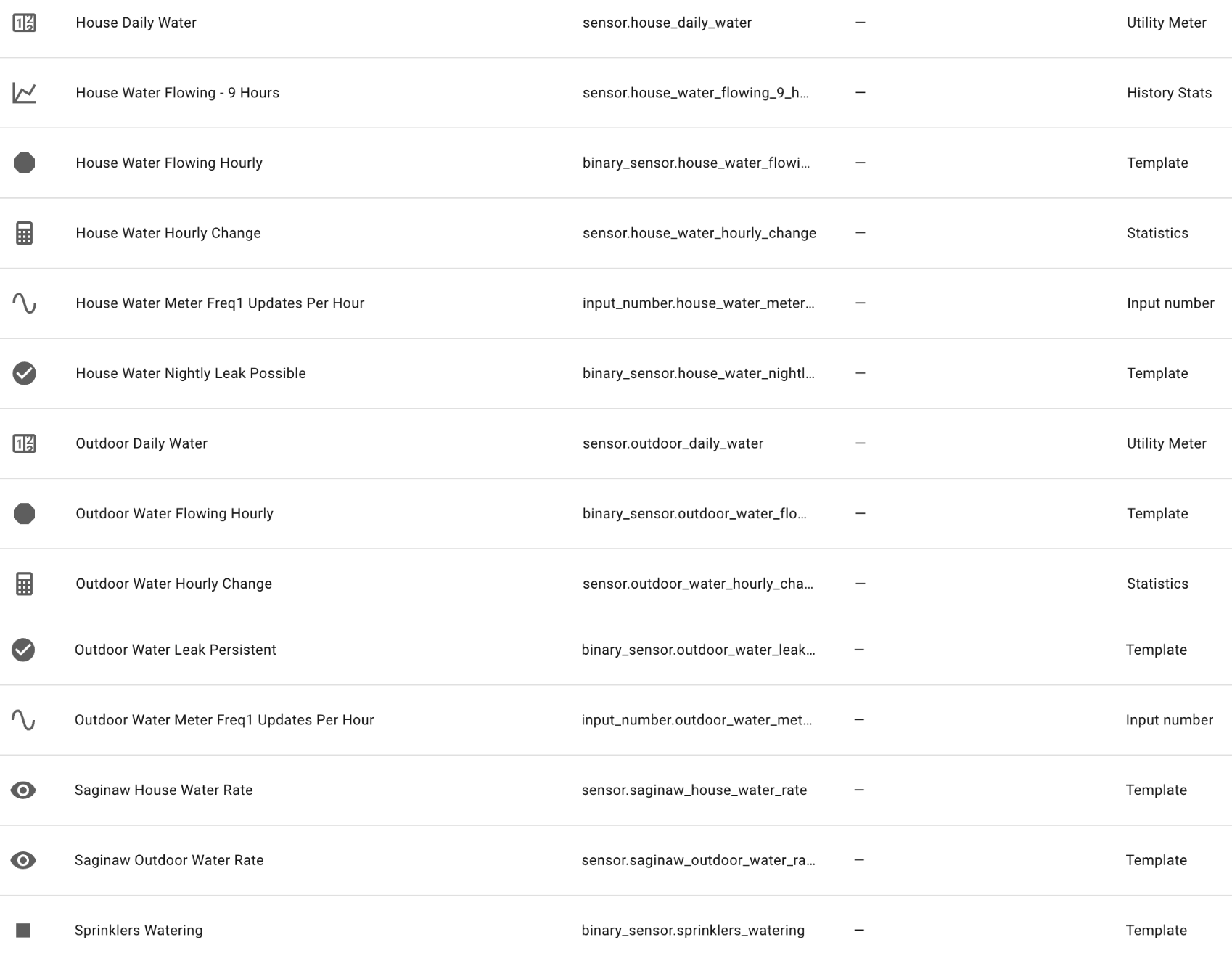

In Devices -> Helpers there are a bunch, but some come from templates above and others when you add the water data to your Energy dashboard (after a reboot and data starts coming in). Here’s my list of helpers:

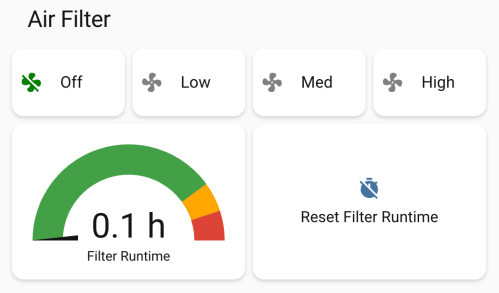

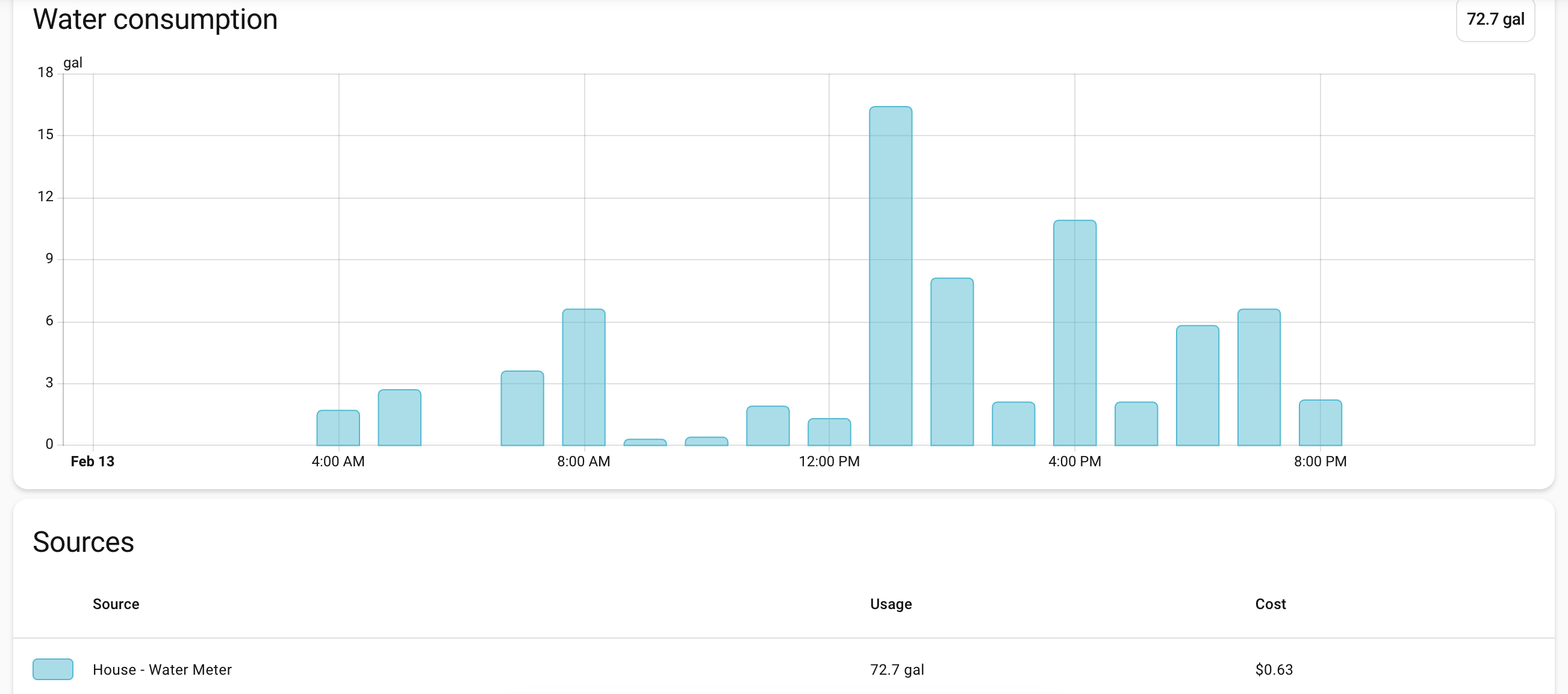

Some key findings when I started looking at the data. My meters are broadcasting many times per minute, but the gallons used reading only changes at 11 minutes after every hour. They do this to save the endpoint battery I guess. So no realtime data, but hourly is better than nothing.

In the data, there is a leaking flag. From what I’ve read this flag only gets turned on if the usage increases for 24 hours straight. Not great for leak detection, but would have been useful last summer when something busted on a sprinkler line and I didn’t find out for a week or so. I have leak notifications based on these flags, but my custom leak notifications should trigger sooner. If the sprinklers have been off and the outdoor usage increases two hours in a row, I’ll get an alert. If the house usage have been increasing all through the overnight I’ll get an alert in the morning.

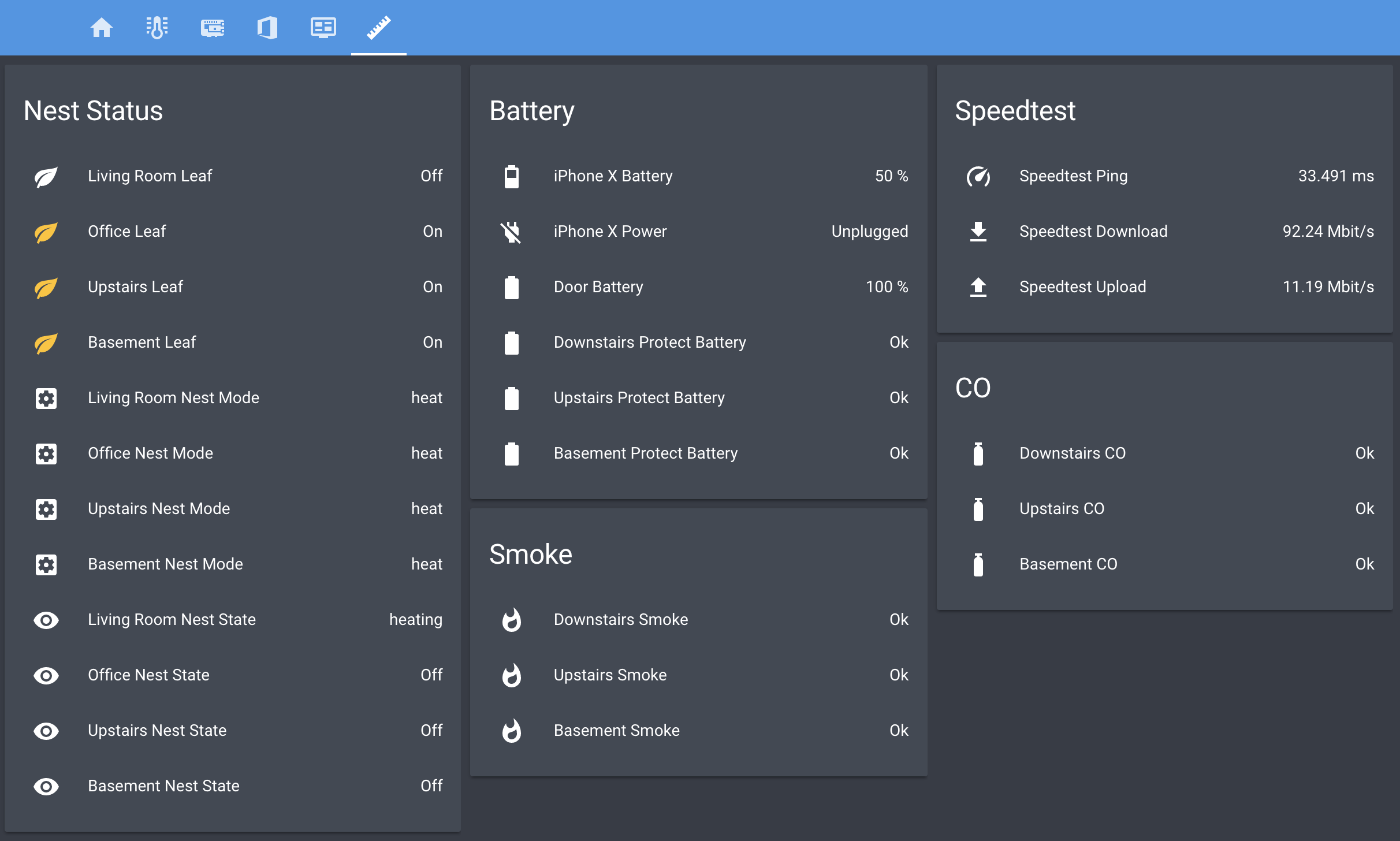

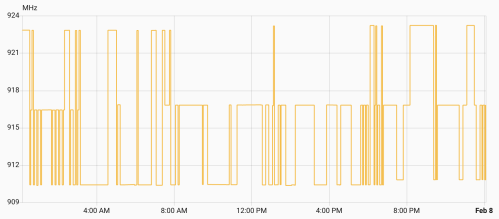

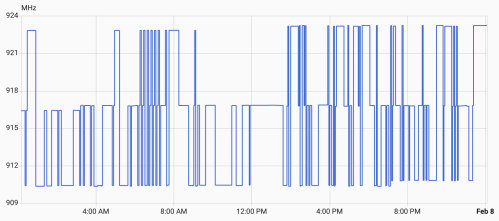

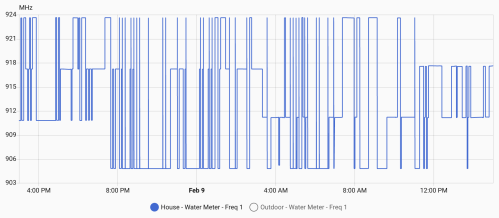

Once everything is setup, let it run. After several days, check out the freq1 sensor data, which should look similar to these graphs.

Your meters might be different, but mine hop between three frequencies at a time. There’s a low, medium, and high. Every 8 hours (3:11am, 11:11am, and 7:11pm), one of the frequencies increases by 400MHz, so over the course of a day they all increase. Then one day they all peaked and reset to the lower end of a frequency band.

From all this data I knew:

- Low Band: 904.8 – 910.8 MHz with changes at 7:11 pm

- Med Band: 911.2 – 917.2 MHz with changes at 3:11 am

- High Band: 917.6 – 923.6 MHz with changes at 11:11 am

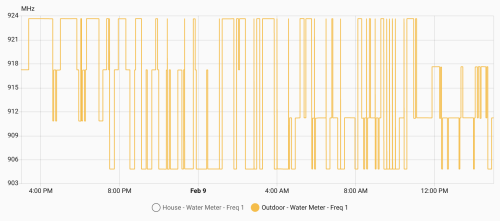

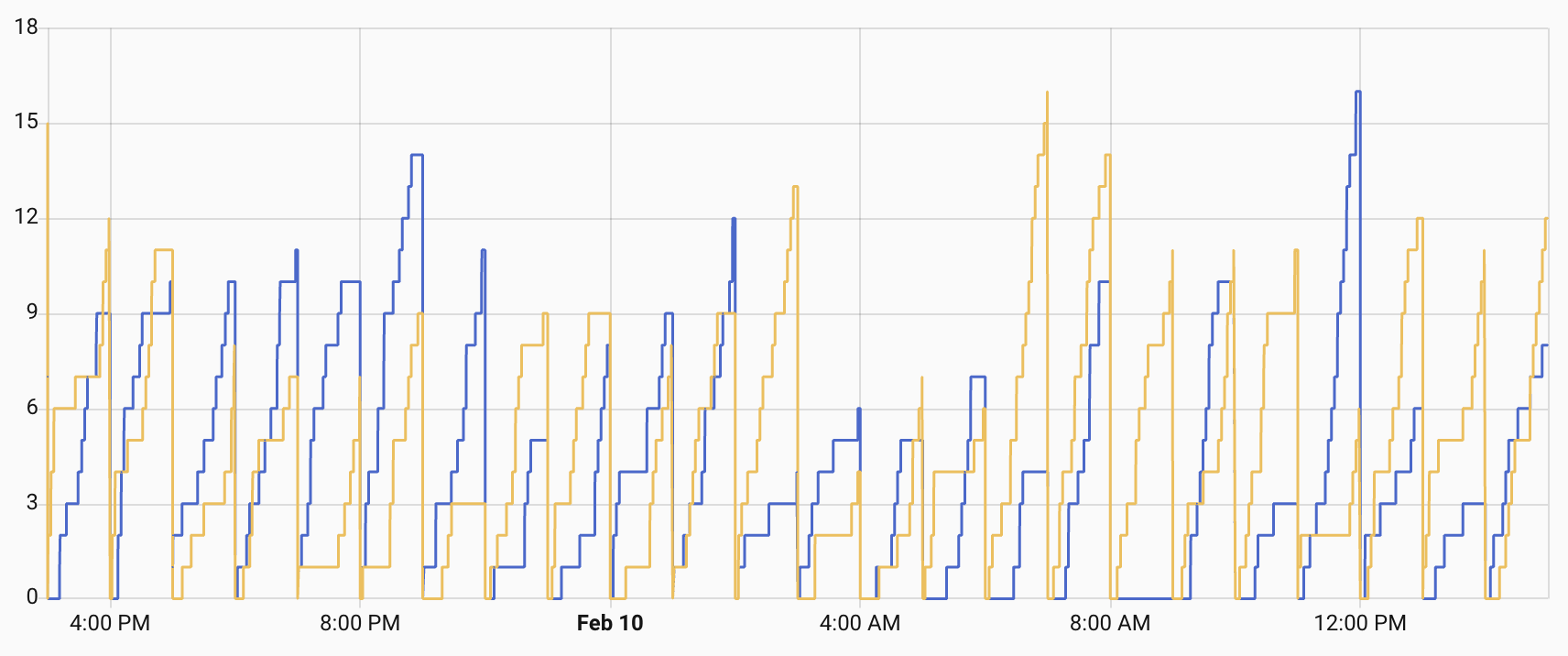

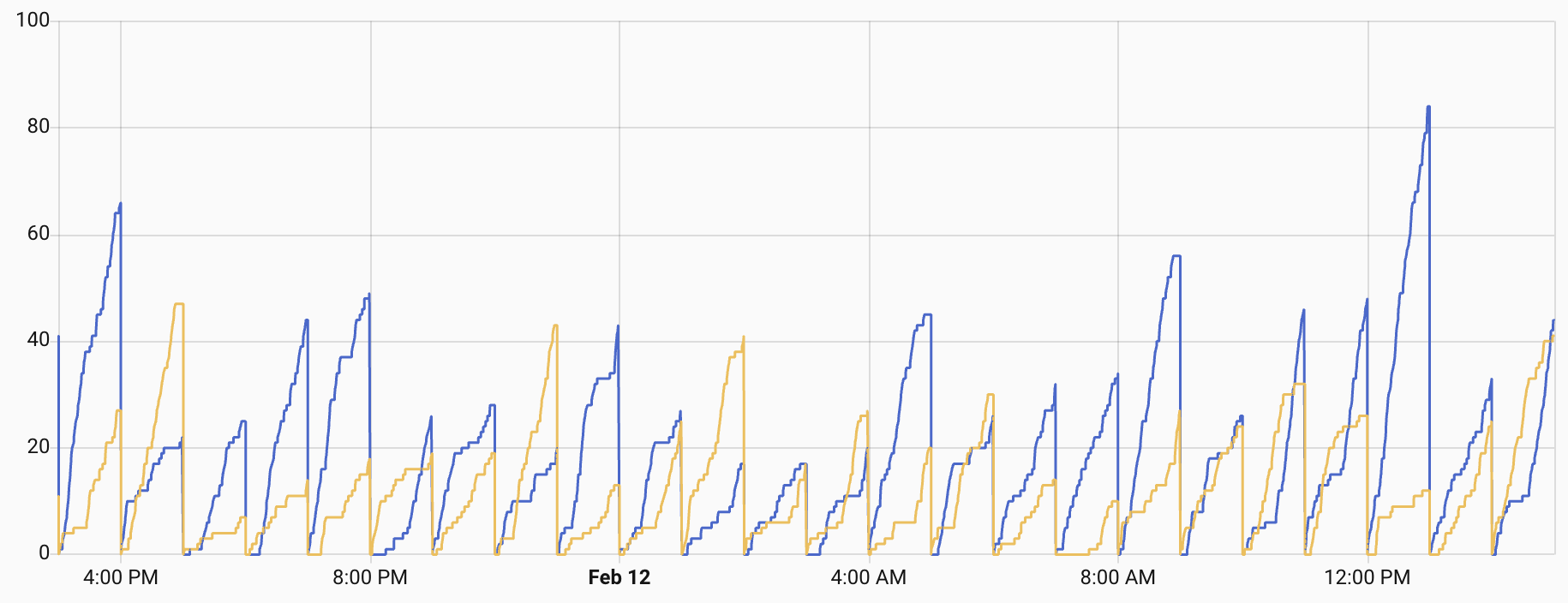

I also tracked how many times per hour I caught data from each meter.

Not bad, but some hours I’d only get one or two data packets for a meter. Technically enough, but there was a risk of missing data. Since I knew the pattern I felt I could do smarter frequency hopping with my SDR to listen for data and then capture a lot more. It worked!

I was getting a lot more reads and rarely less than 10 in any hour. In order to do this I updated the rtl_433.conf file to replace the 24 frequencies with three bands.

# Low band - shifts at 7:11 PM ET (904.8 - 910.8 MHz)

frequency 904.6M

frequency 905.0M

#frequency 905.4M

#frequency 905.8M

#frequency 906.2M

#frequency 906.6M

#frequency 907.0M

#frequency 907.4M

#frequency 907.8M

#frequency 908.2M

#frequency 908.6M

#frequency 909.0M

#frequency 909.4M

#frequency 909.8M

#frequency 910.2M

#frequency 910.6M

#frequency 911.0M

# Mid band - shifts at 3:11 AM ET (911.2 - 917.2 MHz)

frequency 911.0M

frequency 911.4M

#frequency 911.8M

#frequency 912.2M

#frequency 912.6M

#frequency 913.0M

#frequency 913.4M

#frequency 913.8M

#frequency 914.2M

#frequency 914.6M

#frequency 915.0M

#frequency 915.4M

#frequency 915.8M

#frequency 916.2M

#frequency 916.6M

#frequency 917.0M

#frequency 917.4M

# High band - shifts at 11:11 AM ET (917.6 - 923.6 MHz)

frequency 917.4M

frequency 917.8M

#frequency 918.2M

#frequency 918.6M

#frequency 919.0M

#frequency 919.4M

#frequency 919.8M

#frequency 920.2M

#frequency 920.6M

#frequency 921.0M

#frequency 921.4M

#frequency 921.8M

#frequency 922.2M

#frequency 922.6M

#frequency 923.0M

#frequency 923.4M

#frequency 923.8M

# ^ keep blank line

The two uncommented frequencies in each band are the ones on either side of the frequency currently used by the meters. I added a scripts folder and a new update_rtl433_channels.sh file in there.

#!/bin/bash

# update_rtl433_channels.sh

#

# Advances one band's frequency pair in the rtl_433 config.

# Finds the two uncommented frequencies in the band's section,

# comments out the first one, and uncomments the next one after the pair.

# If the pair is at the end of the section, wraps to the first two.

#

# Usage: update_rtl433_channels.sh <low|mid|high> [config_path]

BAND="$1"

CONFIG_PATH="${2:-/config/rtl_433/rtl_433.conf}"

if [ -z "$BAND" ]; then

echo "Usage: $0 <low|mid|high> [config_path]"

exit 1

fi

if [ ! -f "$CONFIG_PATH" ]; then

echo "Error: Config file not found: $CONFIG_PATH"

exit 1

fi

# Determine the section header

case "$BAND" in

low) SECTION="# Low band -" ;;

mid) SECTION="# Mid band -" ;;

high) SECTION="# High band -" ;;

*) echo "Error: band must be low, mid, or high"; exit 1 ;;

esac

# Find start line of this section

SECTION_START=$(grep -n "$SECTION" "$CONFIG_PATH" | head -1 | cut -d: -f1)

if [ -z "$SECTION_START" ]; then

echo "Error: Could not find section '$SECTION' in config"

exit 1

fi

# Find end line: next section header or end of file

NEXT_SECTION=$(tail -n +$((SECTION_START + 1)) "$CONFIG_PATH" | grep -n "^# .* band -" | head -1 | cut -d: -f1)

if [ -z "$NEXT_SECTION" ]; then

SECTION_END=$(wc -l < "$CONFIG_PATH")

else

SECTION_END=$((SECTION_START + NEXT_SECTION - 1))

fi

echo "Band: $BAND (lines $SECTION_START-$SECTION_END)"

# Get absolute line numbers of all active (uncommented) frequency lines in this section

ACTIVE_ABS=()

for LINE_NUM in $(seq "$SECTION_START" "$SECTION_END"); do

if sed -n "${LINE_NUM}p" "$CONFIG_PATH" | grep -q "^frequency "; then

ACTIVE_ABS+=("$LINE_NUM")

fi

done

if [ "${#ACTIVE_ABS[@]}" -ne 2 ]; then

echo "Error: Expected 2 active frequencies, found ${#ACTIVE_ABS[@]}"

exit 1

fi

FIRST_ABS=${ACTIVE_ABS[0]}

SECOND_ABS=${ACTIVE_ABS[1]}

echo "Active:"

echo " Line $FIRST_ABS: $(sed -n "${FIRST_ABS}p" "$CONFIG_PATH")"

echo " Line $SECOND_ABS: $(sed -n "${SECOND_ABS}p" "$CONFIG_PATH")"

# Find the next commented frequency line after the second active one

NEXT_COMMENTED=""

for LINE_NUM in $(seq $((SECOND_ABS + 1)) "$SECTION_END"); do

if sed -n "${LINE_NUM}p" "$CONFIG_PATH" | grep -q "^#frequency "; then

NEXT_COMMENTED=$LINE_NUM

break

fi

done

if [ -z "$NEXT_COMMENTED" ]; then

# At end of section — wrap to first two

echo "End of section, wrapping to first two"

# Comment out both active lines

sed -i "${FIRST_ABS}s/^frequency /#frequency /" "$CONFIG_PATH"

sed -i "${SECOND_ABS}s/^frequency /#frequency /" "$CONFIG_PATH"

# Find the first two commented frequency lines in the section

WRAP_LINES=()

for LINE_NUM in $(seq "$SECTION_START" "$SECTION_END"); do

if sed -n "${LINE_NUM}p" "$CONFIG_PATH" | grep -q "^#frequency "; then

WRAP_LINES+=("$LINE_NUM")

if [ "${#WRAP_LINES[@]}" -eq 2 ]; then

break

fi

fi

done

for ABS in "${WRAP_LINES[@]}"; do

sed -i "${ABS}s/^#frequency /frequency /" "$CONFIG_PATH"

done

else

# Normal advance: comment the first, uncomment the next

echo "Advancing: commenting line $FIRST_ABS, uncommenting line $NEXT_COMMENTED"

sed -i "${FIRST_ABS}s/^frequency /#frequency /" "$CONFIG_PATH"

sed -i "${NEXT_COMMENTED}s/^#frequency /frequency /" "$CONFIG_PATH"

fi

echo ""

echo "Active frequencies:"

grep "^frequency " "$CONFIG_PATH"

This file needs a permissions change. Install the Terminal & SSH app in HA, start it, open it, and type:chmod +x /config/config/update_rtl433_channels.sh.

In configuration.yaml:

shell_command:

rtl433_shift_low: 'bash /config/scripts/update_rtl433_channels.sh low /config/rtl_433/rtl_433.conf'

rtl433_shift_mid: 'bash /config/scripts/update_rtl433_channels.sh mid /config/rtl_433/rtl_433.conf'

rtl433_shift_high: 'bash /config/scripts/update_rtl433_channels.sh high /config/rtl_433/rtl_433.conf'

In automations.yaml:

- id: '1770813439694'

alias: RTL 433 - Shift Low Band Frequencies

description: Advances low band frequencies at 7:11 PM ET daily

triggers:

- trigger: time

at: '19:11:00'

actions:

- action: shell_command.rtl433_shift_low

- delay:

seconds: 5

- action: hassio.addon_restart

data:

addon: 9b13b3f4_rtl433-next

mode: single

- id: '1770813477228'

alias: RTL 433 - Shift Mid Band Frequencies

description: Advances mid band frequencies at 3:11 AM ET daily

triggers:

- trigger: time

at: 03:11:00

actions:

- action: shell_command.rtl433_shift_mid

- delay:

seconds: 5

- action: hassio.addon_restart

data:

addon: 9b13b3f4_rtl433-next

mode: single

- id: '1770813511146'

alias: RTL 433 - Shift High Band Frequencies

description: Advances high band frequencies at 11:11 AM ET daily

triggers:

- trigger: time

at: '11:11:00'

actions:

- action: shell_command.rtl433_shift_high

- delay:

seconds: 5

- action: hassio.addon_restart

data:

addon: 9b13b3f4_rtl433-next

mode: single

Make sure to uncomment the correct pair of frequencies in each band, update the automation trigger times, and make sure the slug for the rtl433-next app is correct. Each time an automation runs the active frequencies are updated for the associated band. Since they should be on both sides of the frequency used by the water meter both can read the RF broadcasts. When it gets to the end of the band’s frequency list, it shifts up to the top of the list.

A lot of this is dependent on your water meters and situation, but hopefully it gives you enough information to make it work.