Yesterday I set out to fix a couple of things around the house.

Garbage Disposal

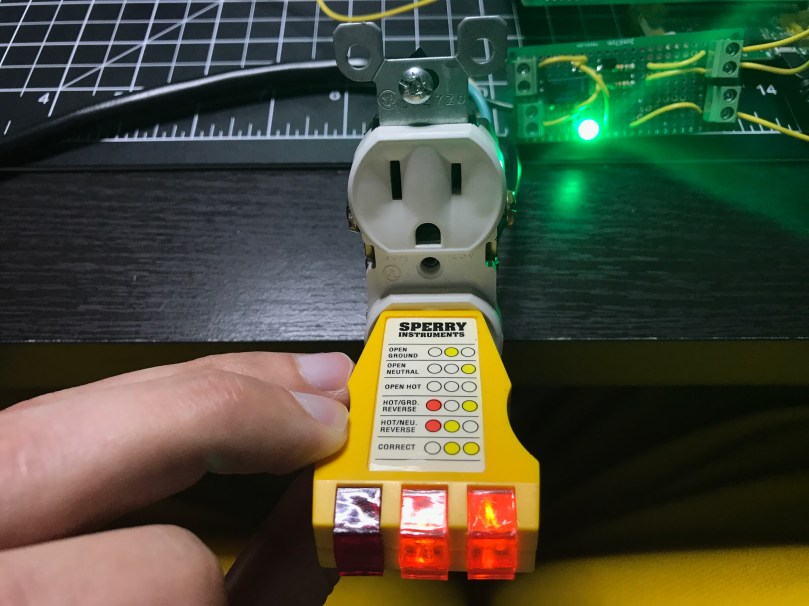

It stopped working several weeks ago when the cleaning lady was using it. I was out golfing at the time so have no idea what happened. There was no sound or anything when the switch was flipped. My first step was to make sure the outlet worked.

So then I moved everything out from under the sink, got a bucket to catch the water, and removed the unit. I noticed a red button on the bottom.

It responded like the button on a GFI outlet. Then I plugged the disposal back in. There was a humming sound for a few seconds and then it stopped. The red button had popped out. Must be some kind of safety mechanism so the unit doesn’t burn up the motor. While cleaning out the cupboard I had come across an allen wrench.

There was also a hole in the bottom of the disposal where this fit. Gave it a bunch of turns and it started to feel pretty smooth. Pushed in the button, started plugging it in, and holy shit! The torque on that thing nearly sent it flying across the room. Glad I had barely touched the plug to power because my hand was able to jerk it away from the outlet.

I put the garbage disposal back in place, reconnected all the pipes, and I was back in business. No leaks either. Something must have been jammed inside.

As a bonus it turned out to be a good reason to clean the cupboards under the sink, which had accumulated a bunch of junk.

Garage Door Opener Light

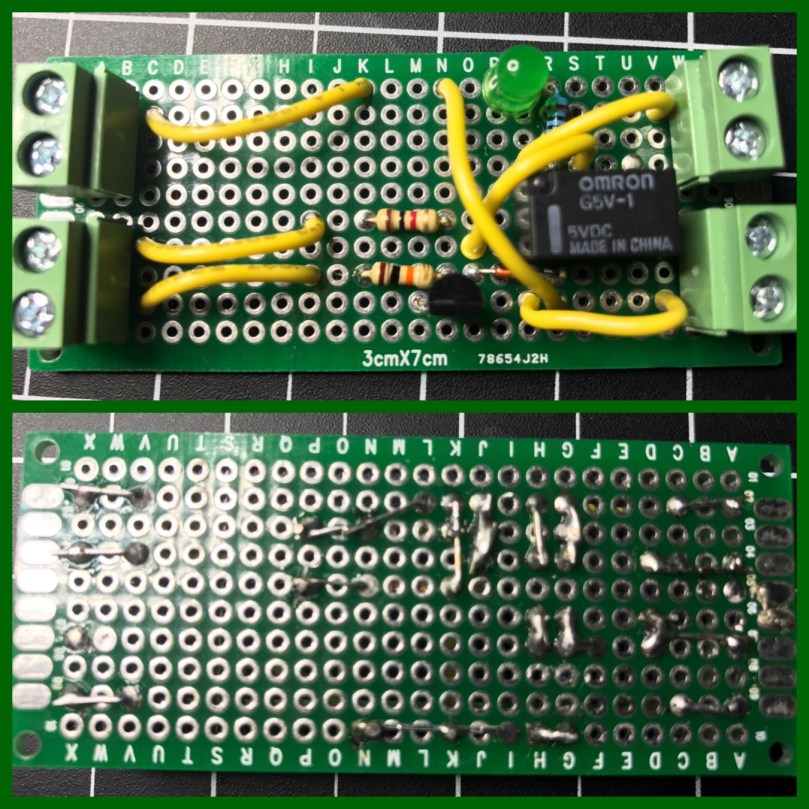

It’s been flaky for several years. I had tried replacing bulbs and sometimes they would work for a bit or flicker here and there, but eventually stop working. With my new knowledge and confidence with electricity and circuits I figured there had to be something going on with the connection. After unplugging the garage door opener, I took off the face plate and disconnected the wires from the back of the light socket.

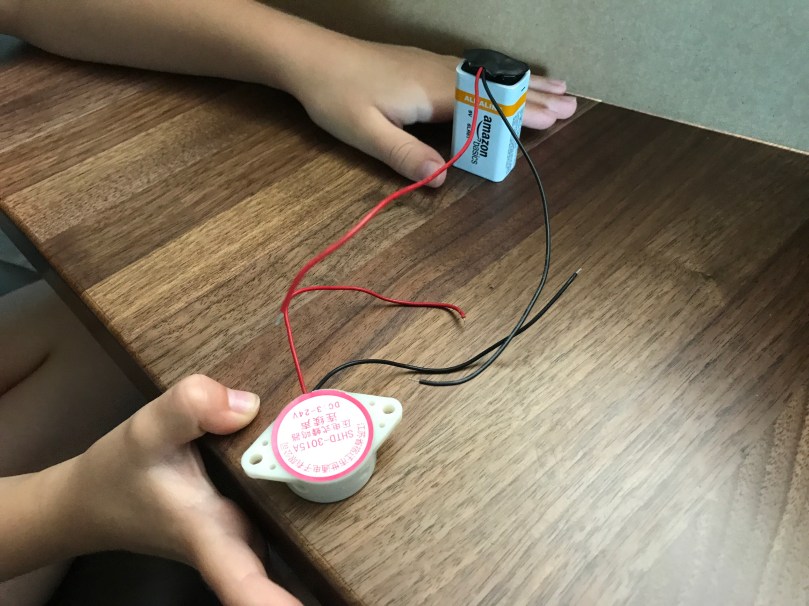

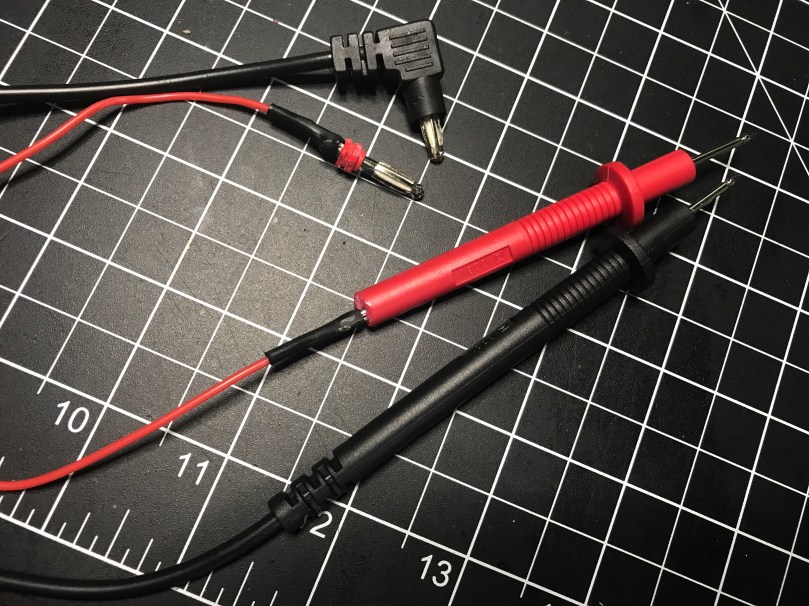

Looking at this socket, 2 things stood out to me: 1) seems like both contact points were corroded and 2) unlike a lot of light bulb sockets where the sides are metal, this only had the contact pad which is at about 1:00 if this were a clock face. I grabbed my favorite tool, the digital multimeter…

I may have been able to clean up the contacts on the socket, but I figured it was better to replace it. The only thing at Home Depot that looked like it would work was this waterproof light socket for $3.47.

I carved off some of the rubber with an X-ACTO knife for a better angled fit and applied a bunch of hot glue. Here are views of the front and back…

It ended up working much better than expected. I reassembled everything, plugged in the garage door opener, and voila!

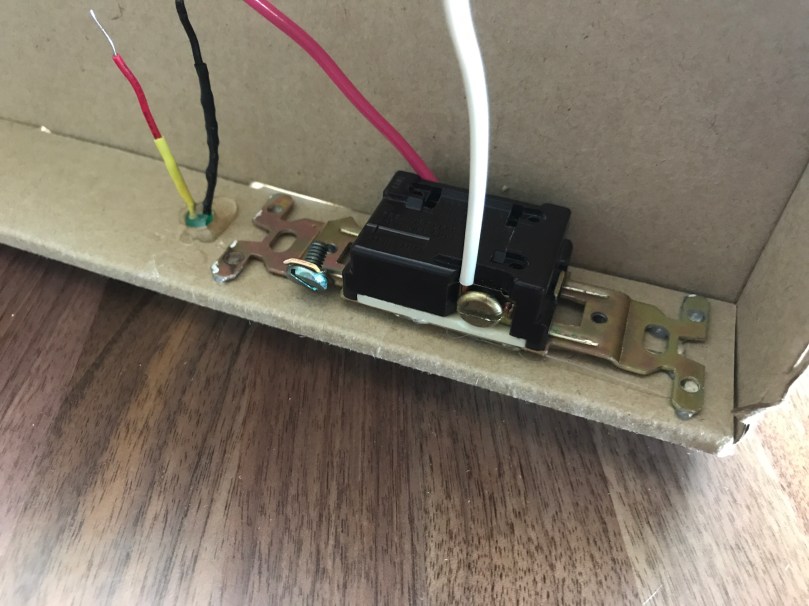

I also replaced a 3-way light switch I could hear shorting out, but it was an ordinary replacement job.