A week after moving in, Dad came down and we built a wall in the basement to close off the workshop and keep sawdust contained. I eventually finished the rest of the show side of the wall and added trim to the door.

The Cat6 cables and networking rack are a project I hope to tackle over the holidays.

In order to keep as much dust as possible in the shop, I bought a can of spray foam to fill gaps around pipes, ducts, and beams. Since I hade some large gaps, I had to do two applications. I used wider painter’s tape to hold the foam back (picture below was taken during round two).

Then I wired all of the shop outlets and put up OSB for my wall material. It was a cheap option at about $15 a sheet, while allowing me to screw lighter things anywhere. The first things to go on the wall were all of my Ryobi storage, since the tools had been scattered across the floor for weeks. I absolutely love the 10 foot foundation, which allowed me to put wood storage high and out of the way.

I put up my clamp racks and emptied a lot of boxes to organize my tool wall. The Allen key holder was a quick side project.

I replaced all of the lighting in the gym and the workshop with a 10 pack of 4′ LED light fixtures for $76 from Amazon and it made a big difference. Here’s a before and after of the gym.

I had wanted a SawStop for years and the move seemed like good excuse to sell my old Craftsman table saw instead of hauling it to a new basement. I bought SawStop’s Contractor Saw with the 36” T-Glide Fence Assembly, Mobile Base, and Cast Iron Wings. She’s a beauty, a joy to use, and the safety features can’t be beat.

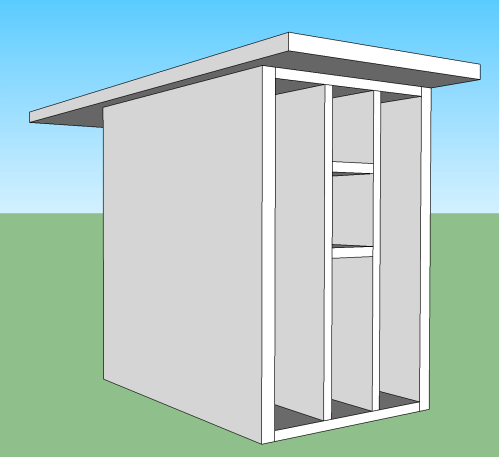

I had a general idea of the layout I was going for in the shop, but in order to get a feel for the space, I measured all of my carts and tools so I could model in SketchUp. I started with the structure, items on the main wall, and things that can’t be moved, like pipes and the shop sink.

Then I needed all of the tool and storage carts. I imported a lot of the items from SketchUp’s 3D Warehouse and scaled everything to the correct size.

Eventually I got to a comfortable arrangement in the model and could physically put things in place. Over the course of several weeks I made a lot of adjustments. I even moved my band saw over to the drill press cart so I could repurpose it’s cart for my planer. I think I ended with a very good first iteration. Here are comparisons of the model and the actual room.

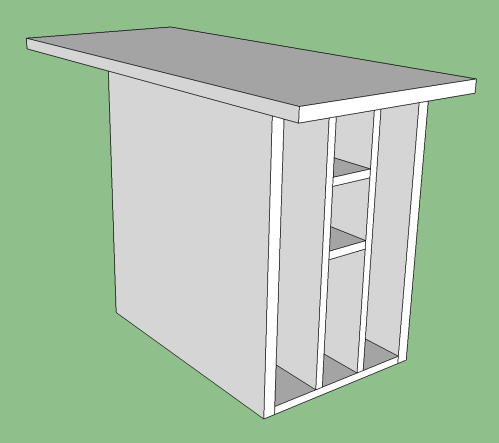

I can start making things again! One of the first builds is going to be an outfeed/assembly table for the table saw. It’ll have some neat features and storage. In the models I made a table top of about the correct size and in real life you see my old table top, which is too small and low, on saw horses.