After I improved the lathe table in September I actually did start on a belt guard for about 15 minutes and then didn’t touch it for weeks. Happy to say I finally got back to the project and ended up making a guard for each belt.

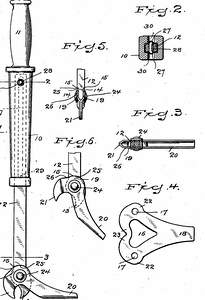

According to the product manual, here’s a sketch of the main belt guard.

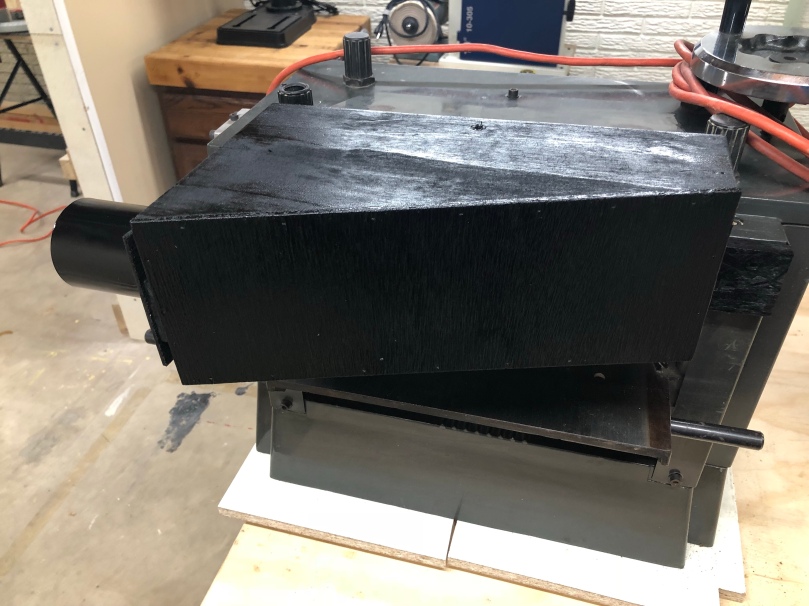

I actually found one for sale on eBay and here are pics from that listing.

The pictures of the speed chart turned out to be especially useful because I was able to manipulate them in a graphics app to create my label.

This was a fun build where I got to try a lot of new things. I hadn’t created a video in a long time and it showed because there were several times when I forgot to turn the camera on or off. I tried some new editing stuff too, like sequences for repetitive build actions.

I need a simple project to learn how to use the lathe. Any suggestions?

Earlier this summer, I came across an auction online with a bunch of tools. The items were located up in Alpena and I was heading up to Long Lake for our family vacation in a few days. That’s only 10 miles north of town, so if I won anything I could pick it up locally instead of paying for shipping or needing to have my Dad pick it up. I bid on a few items, not really expecting anything, so I was surprised when I got an email telling me I “won” a lathe.

Earlier this summer, I came across an auction online with a bunch of tools. The items were located up in Alpena and I was heading up to Long Lake for our family vacation in a few days. That’s only 10 miles north of town, so if I won anything I could pick it up locally instead of paying for shipping or needing to have my Dad pick it up. I bid on a few items, not really expecting anything, so I was surprised when I got an email telling me I “won” a lathe.