While cleaning up the feed rollers on my Dad’s Craftsman 351.233831 Planer I noticed there were really beat up.

Unfortunately the part (#8520) is discontinued and I couldn’t find an aftermarket one anywhere online. I stumbled across some forum posts discussing roller resurfacing, so I got some quotes.

Mid American Rubber, which is actually here in Michigan, wanted $137 for each roller!

J. J. Short Associates, Inc. quoted $92.50 for one or $85 each if I did both.

These first two had big forms on their website with diagrams showing how to get all of the measurements they requested.

I had to call Feedrollers.com and provide some info. A day later they got back to me with a price of $57 each.

Western Roller Corporation had an online form but it was very basic so I only provided the model of the planer and the part number. I got an email saying, “most of these small table-top type planers we recover your existing shafts for $65.00 to $100.00 each.” That’s a pretty wide range, so I sent over the measurements provided to the other companies and they quoted $68.88 each.

I went with the cheapest one since these aren’t for a production shop of any kind. I shipped out the rollers and got them back exactly 3 weeks later.

I’m really impressed with these. Hopefully they hold up well for my Dad. After installing the rollers I swapped out and aligned all of the cutter knives. With this and all of the previous work, the planer runs like a brand new machine.

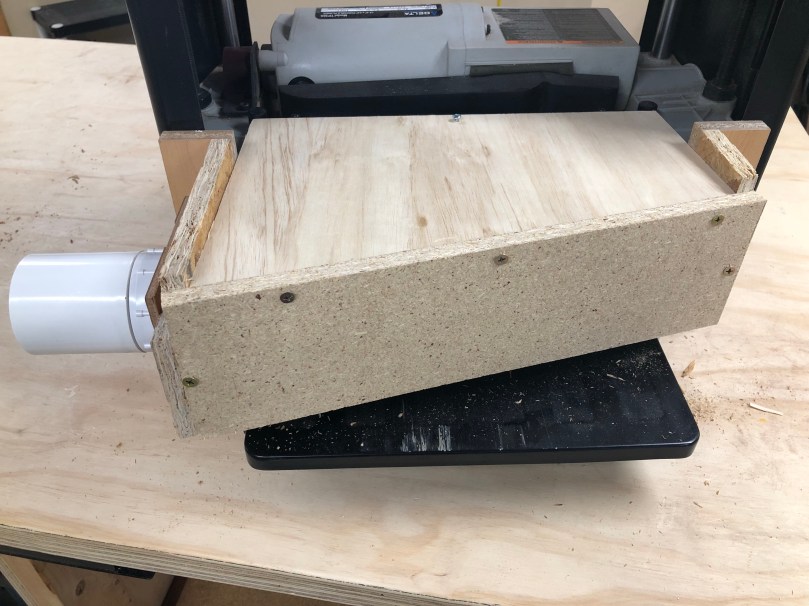

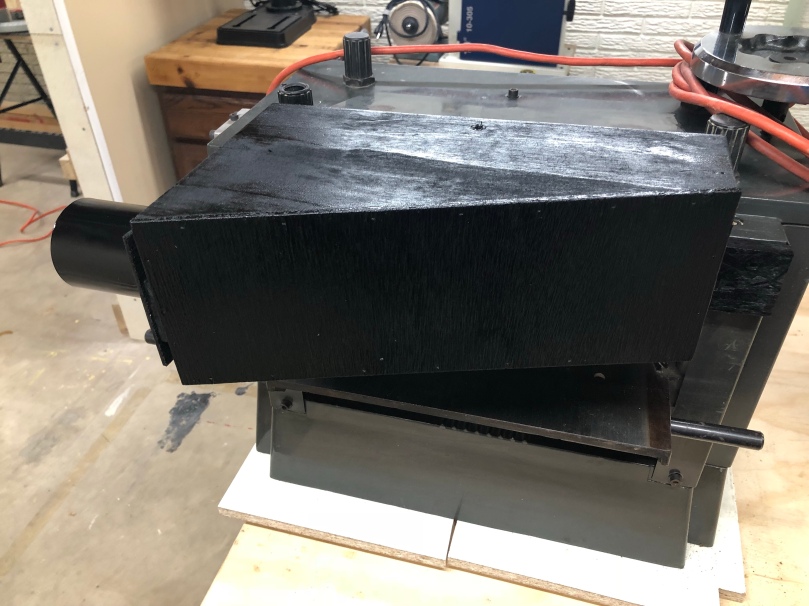

When Delta produced this planer, the dust collection attachment was an extra accessory. I decided to make my own because I don’t understand this design. Why would you want your hose hanging over the outfeed? Too much risk of the work piece getting jammed on the way out, which is extremely dangerous.

When Delta produced this planer, the dust collection attachment was an extra accessory. I decided to make my own because I don’t understand this design. Why would you want your hose hanging over the outfeed? Too much risk of the work piece getting jammed on the way out, which is extremely dangerous.