I needed a few easy things to tackle over the weekend and since we’ll be losing a little bit of storage space (though gaining some new space) as part of the kitchen remodel, I wanted to make better use of wasted space in some areas.

First up was a small cabinet between the range and dishwasher where we store our baking sheets, cutting boards, and other similar size items. The top 1/3 or so of it was dead space, so I added a couple of shelves made from scrap wood.

Now we have a spot for aluminum foil, wax paper, plastic wrap, parchment paper, and ziplock bags. This freed up two entire drawers in the island.

The second task has been on my ideas list for at least six months. The pantry cabinet in our kitchen had three large drawers, spaced way too far apart. There simply are not that many tall food items, at least not the stuff we buy.

With the cabinet being so tall it’s hard to get a feel for the space in this picture, but you can see the top drawer, with our tallest items, had quite a bit of wasted space above it. I decided to leave it where it was for flexibility and because it’s already hard to see what’s in there. I moved the second drawer up 2-1/4 inches and the third drawer up 7-1/8 inches.

This gave me plenty of space to add a fourth drawer. I still had this one with slides sitting in the basement after taking apart a tower of drawers four years ago.

Unfortunately it was too wide, so I had to take it apart and make it narrower. I decided to make it shorter as well to match the others. By chance it was already the same depth.

Something I wasn’t thinking about when I moved the drawers was the areas meant to be handles were now really close to the bottom of the drawer above, begging for smashed fingers and an F-bomb.

I always thought it was an odd design for a drawer pull to be honest. I made a template for the drawer fronts and cut the other drawers to match. I also used a roundover bit on those front edges.

I measured out the placement, installed the drawer slides, and slid in the “new” drawer. Who doesn’t love more storage space? Especially for food!

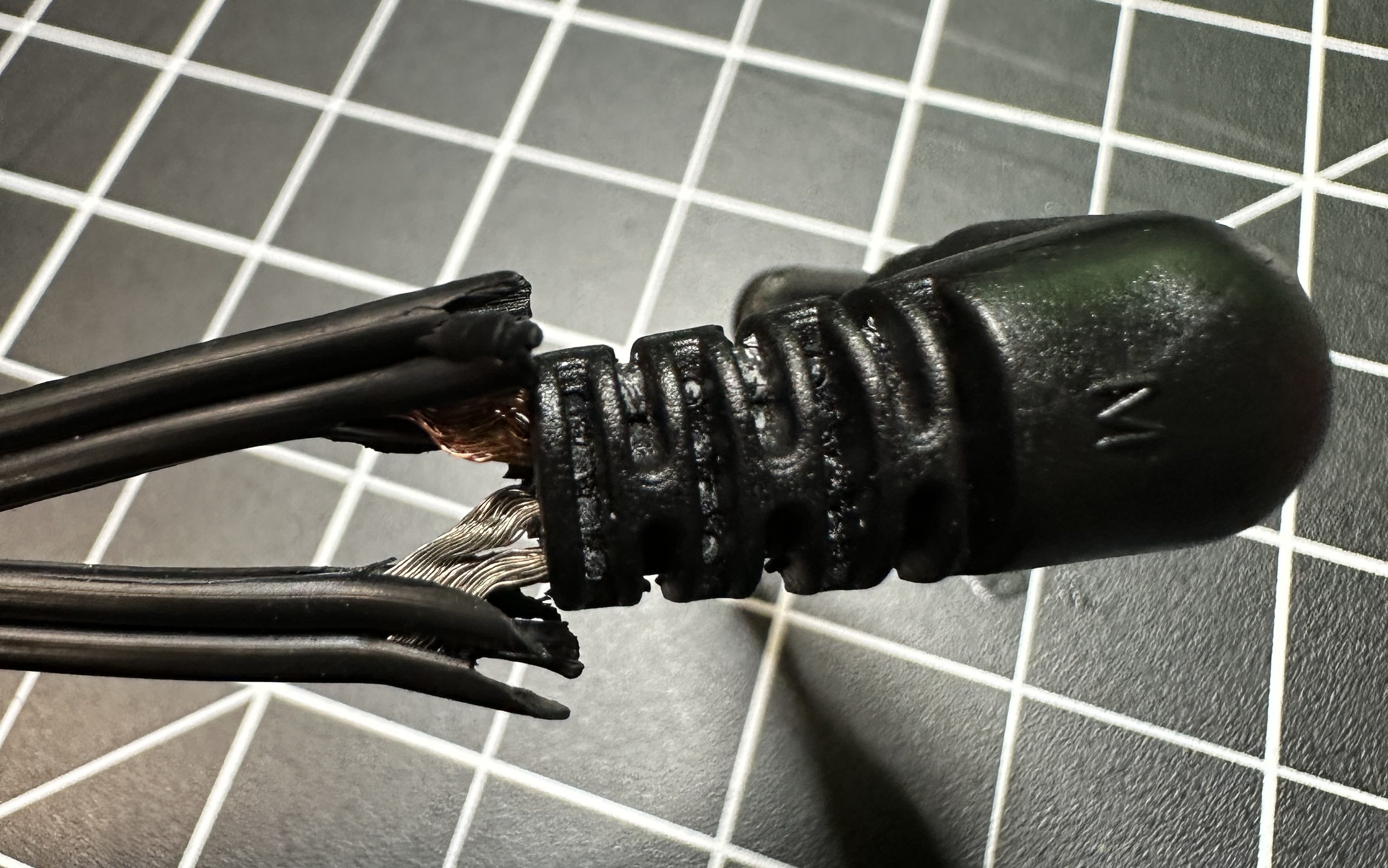

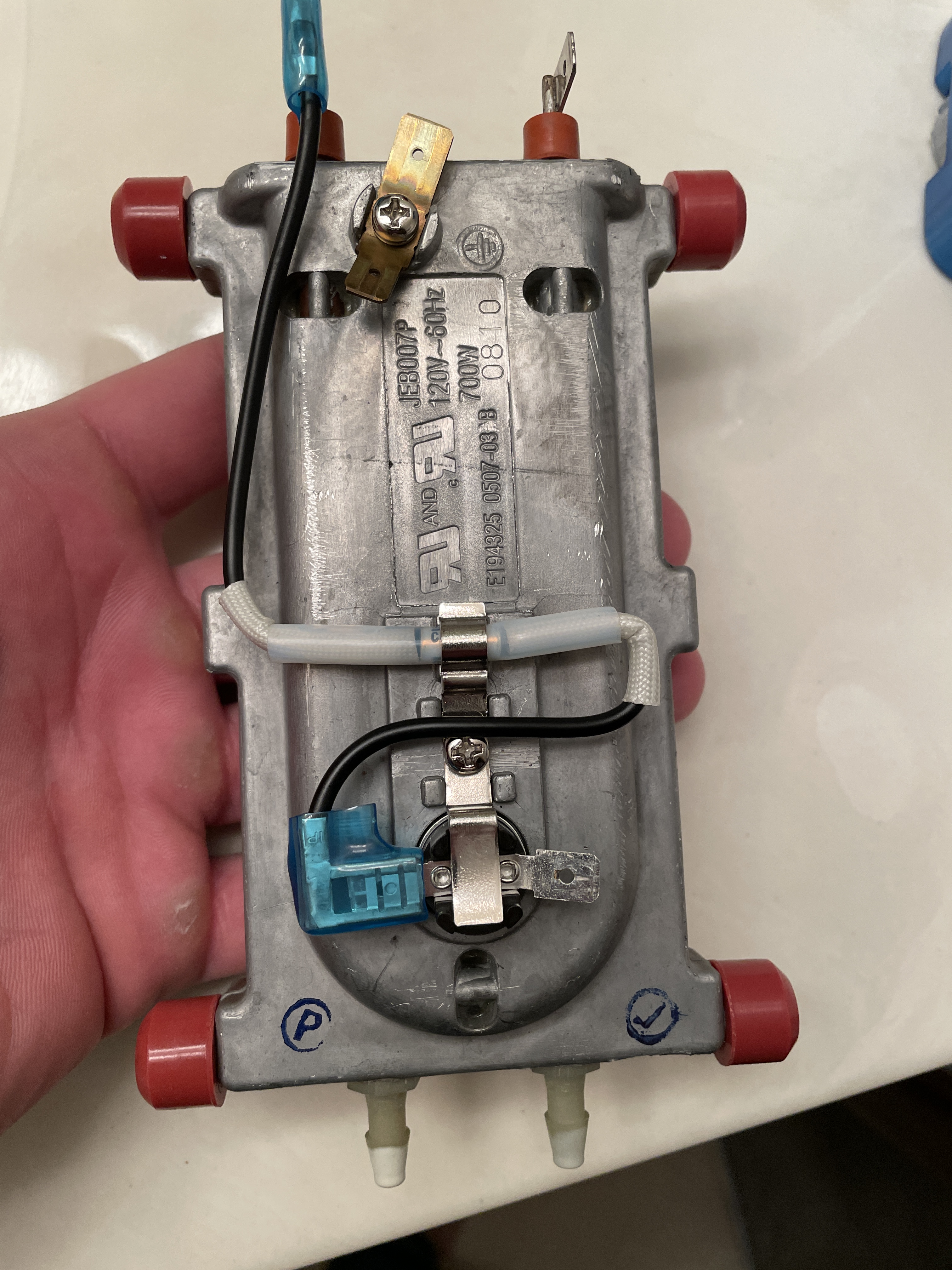

I’ll paint the drawer fronts when all of the cupboards get painted. A third bonus improvement was a quick fix for this utensils drawer, which has been busted for years. I’m surprised it hadn’t fallen apart completely.

I cut a piece of wood for the corner, added glue and brad nails, and called it good.

All fairly quick and easy projects that improved our kitchen organization.