I’m going to build a bluetooth speaker for my garage gym using an old set of computer speakers. I thought it would be good to plan it out in a 3D model first, so I learned how to use SketchUp by following their great video tutorials. As I’ve learned new tricks and thought of different ideas there have been several design iterations.

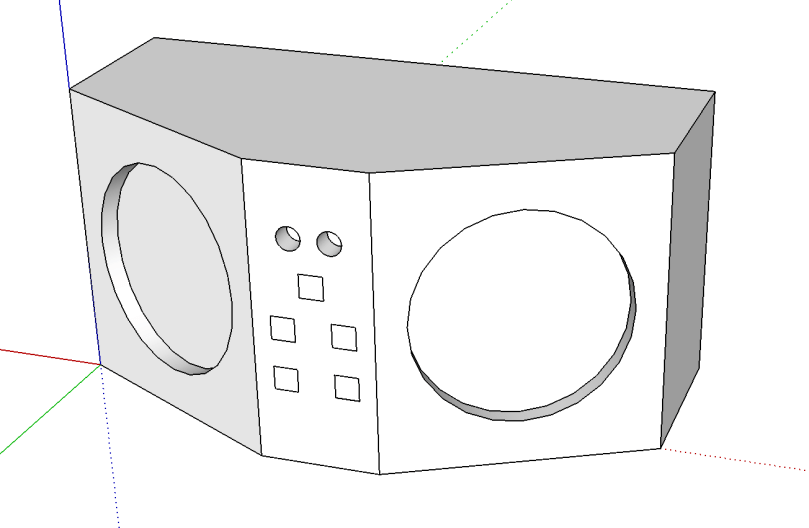

This first attempt was a very rough idea using paper-thin walls or basically one solid piece, depending on how you want to think of it.

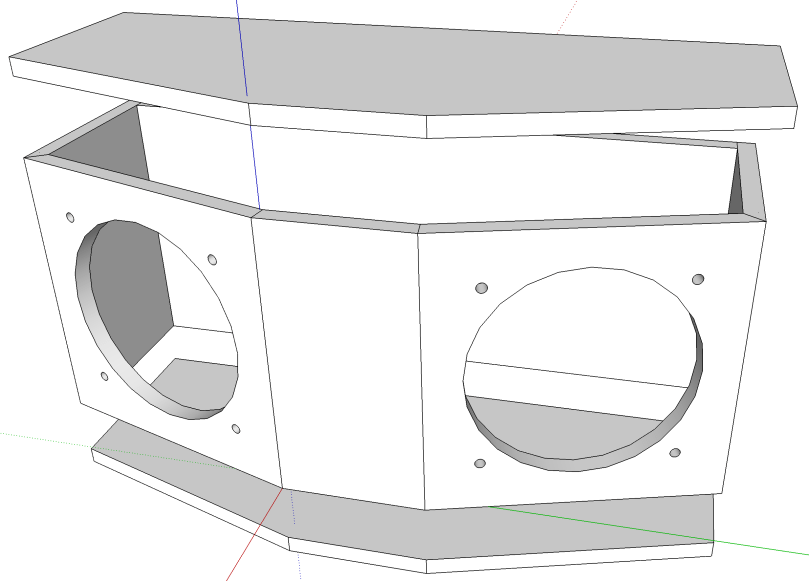

I was thinking I could build the box out of 1/4″ material. I set the thickness of the walls, properly created each side of the box as a separate piece, and separated the lids.

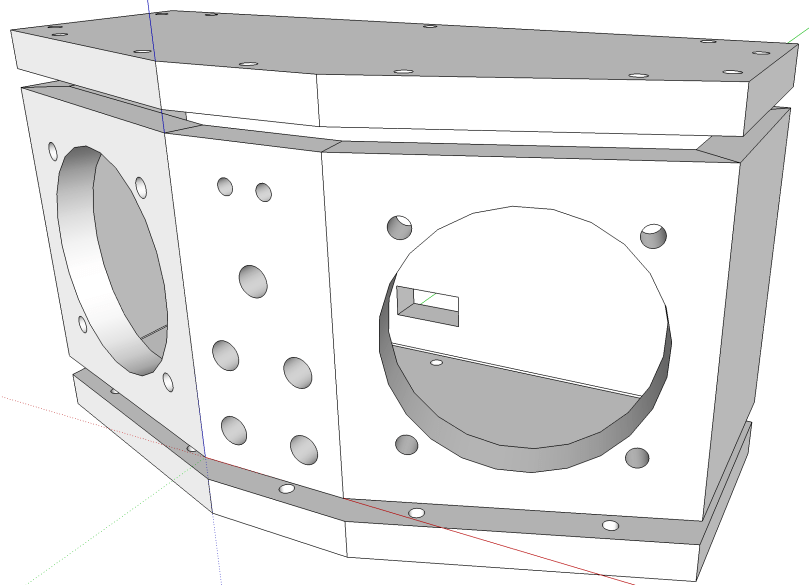

I realized using 1/4″ material wouldn’t give me much room to drive screws into, so I increased to 1/2″. I added speaker mounting holes and the lids were given holes where screws will hold the pieces together. The holes in the middle front section will be where LEDs and buttons go. The square hole in the back wall (which will probably be changed to a small circle and maybe moved to a side) is for the power cord.

I realized if the lids were sitting on the top and bottom of the sides, you’d be able to see the ugly edges if I use something like plywood. So I increased the height of the walls and shrunk the lids to fit inside. There is a row of screw holes all the way around the top and bottom of the side walls, which will attach everything to the lids. I forgot about the on/off switch, so I added another hole on the front.

This is the first time I’ve attempted any 3D modeling and it’s been a lot of fun. Before I start working with wood, I’ll probably create a cardboard model to make sure the components fit inside. The dimensions are roughly 4.25″ deep, 9.5″ wide, and 5″ high.

All of the SketchUp files are in a bluetooth-speaker-design repo on GitHub if you want to use any of them.

Head over to Making a Bluetooth Speaker to see how the build turned out.