The iPhone really did not like me putting the dark glasses over the selfie lens, but it worked. Taken in Saginaw, MI at 3:14pm.

The iPhone really did not like me putting the dark glasses over the selfie lens, but it worked. Taken in Saginaw, MI at 3:14pm.

With our new house having a big walk-in closet we won’t need dressers, so we’ll be selling our bedroom set, which meant it was a good time for new nightstands. Here’s a photo dump of the build.

These will be floating on the wall in the new house, with about five inches of space under them. I did a lot of things in this build I’ve never tried before, so I learned a lot. I love how the decorative grooves turned out on the drawer fronts, which was inspired by something Michael Alm did on his kitchen cupboards. The oak handles were made with inspiration from a couple we liked on Etsy (1 & 2).

I can’t wait to get moved in this summer and mount these on the wall!

This Baja is really good and one of the best Mountain Dew flavors I’ve had in awhile. It has a little fruity kick to it. Solid 8.5 out of 10.

I had high hopes for this one since I like mango and love lemonade. It’s pretty “meh” though and I probably wouldn’t buy one. I’ll give it a 6/10.

Today, my team at Automattic did an hour long painting activity over Zoom. I’ve never done anything like this, so it was fun.

At some point I’ll have to make a frame to hang it on a wall in my workshop.

This Purple Thunder from Mountain Dew is a February 2024 exclusive at Kroger stores. The can describes it as “DEW with a Blast of Berry Plum.”

Not a very good flavor and you can definitely taste, what I assume, is the plum. Has a little medicine taste to it. Only gets a 3/10.

Yesterday I went to make some 45° cuts on the table saw and couldn’t get it past 30°. After a few minutes of tinkering around, I realized there wasn’t enough slack on the wire going to the motor. I guess I wasn’t thinking about when I installed the new switch several years ago.

Instead of replacing the entire wire all the way back to the motor, I added a junction box and an extension to the switch.

The saw still wouldn’t get to 45° though, because I had another issue. I guess I’d never done that much of an angle, so the threaded rod to guide the tilting mechanism was caked with saw dust. After some WD-40, a wire brush, and cranking it back and forth, it was moving well.

I’m loving my new desk. There are a couple of needed improvements though. First, I always have a water bottle, coffee, pop, or several on my desk when working, so I had grabbed this coaster from the living room. It bugged me all week.

Can you believe I’d never made a set of coasters? Time to fix that.

This was a simple project and a lot of fun to knock out something small. I’ll keep two of the coasters in the office and put the other two in the living room.

It was time for a new desk for my home office. I ordered this TOPSKY desk base on Amazon for $220.99.

Over the years, without success, I’ve tried to stand some while working. Hopefully a motorized adjustable base will encourage me to stand for certain tasks and even if I can do a couple of 20-30 minute sessions each day it’ll be a big help.

I got to work processing walnut boards and white oak flooring.

There was a lot of jointing, cross-cutting, ripping, planing, more ripping, and trimming. I’m excited to use that box of off-cuts to make an end grain cutting board or two! I felt like the key to this build was going to be the glue-ups. I started with sections of 9-10 pieces and ended up with eight of those.

I ran each section through the planer, with the help of some shimming for a couple, to flatten them. I made a temporary sled to square up the sides to the faces.

To help assemble the sections, I used a couple of biscuits on each glue joint.

I glued up two sections at a time, which gave me four bigger sections. Then I glued up two of those at a time and one final glue up.

I drilled and put in all of the bolt inserts, which will attach the top to the desk base.

I took three passes with the router to put a big chamfer along the bottom edge.

With a jigsaw, I rough cut out a spot in the back to pass cables through. Then I did some sanding to smooth it out and added a chamfer with the router. Here is it, viewed with the desk bottom facing up.

Due to the base’s cross support, there’s was limited depth for drawers, but there was width for them. I took some old kitchen cabinet drawers, chopped them in half, and closed them up with scrap plywood.

Then I worked on what I’m calling the drawer box even though it’s not a box. I also cut top rails from hardboard and oversized drawer faces from walnut. Grabbed strips of walnut for face-framing and glued together pieces of oak to make drawer pulls.

All the sanding! I went through 80, 120, 180, and 220 grits on the top and sides of the desk.

Time to put some finish on, which is always a favorite step to see how it’s really going to look. It was my first time trying out a hard wax oil and I used Bee Nooba Wax from Bumblechutes. It was very easy to apply and I’ll definitely be using it on future projects. I applied one coat to the bottom and three coats to the sides and top.

Then it was back to the drawers. I stained the “box” black and ended up having to trim some things to fit better around the rail of the desk base. I sized the drawer faces, made oak handles with 10° angles, assembled everything, and applied finish.

It turned out great! I can’t wait to see it in our new house later this year!

Ever since we finalized the floor plans for our new house, I’ve planned to make a physical model. So when we were without power until after 5pm on Saturday, I got most of it built and finished on Sunday.

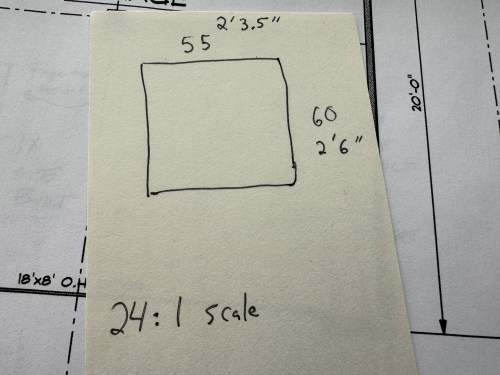

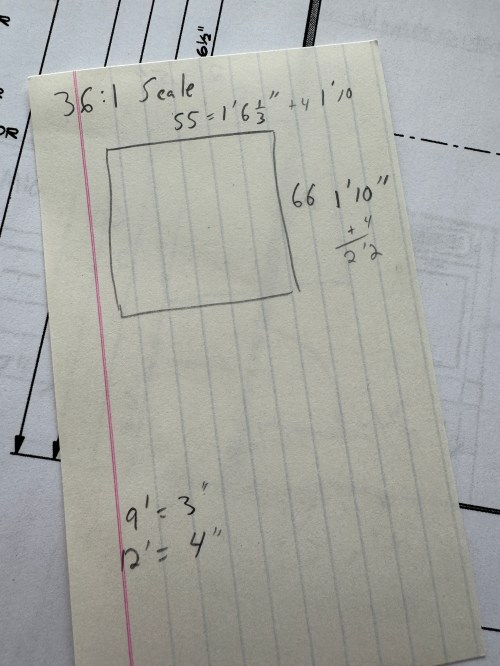

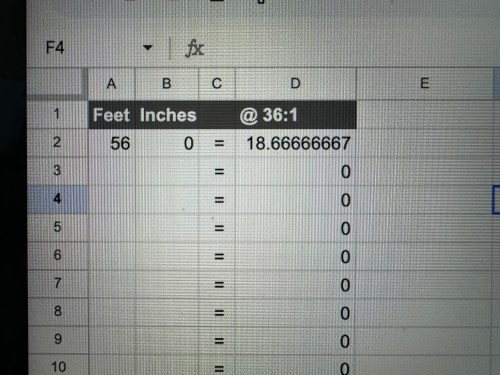

I almost started building at 24:1 scale but realized how big it would be, so I settled on 36:1. I highly recommend the exercise for your office, shop, home, gym, or any other area you spend a lot of time in. A model really helps you get a feel for a space and think about it differently. This isn’t my first model and won’t be my last; I had built my basement, focusing on the workshop, about six years ago.